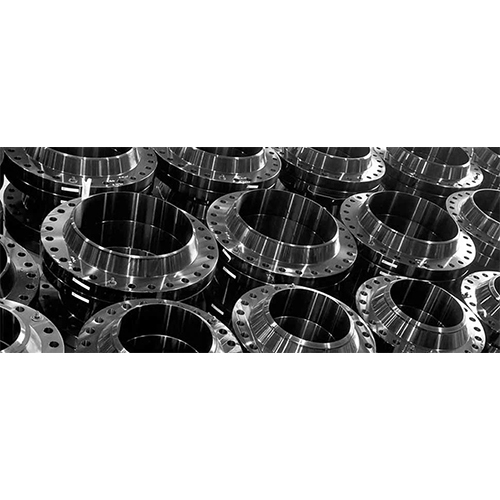

ASTM A181 Flanges

ASTM A181 Flanges Specification

- Feature

- Corrosion Resistant, High Strength, Durable, Precise Dimension

- Purity

- Standard commercial grade

- Dimension (L*W*H)

- As per order/specification

- Application

- Industrial, Oil & Gas, Petrochemical, Power Plant, Chemical, Shipbuilding

- Grade

- Class 60, Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, Class 2500

- Product Type

- Flange

- Material

- Carbon Steel

- Standard

- ASTM A181

- Shape

- Round

- Surface

- Rust Proof

- Connection

- Welded

- Technics

- Forged

- Pressure

- High Pressure

- Size

- Customizable

- Color

- Silver

- Hardness

- 170-235 HB

- Machining Tolerance

- Close tolerance as per drawing/specification

- Packaging

- Wooden Boxes, Pallet Packing, Customized

- Thickness

- As per ANSI/ASME B16.5 & custom requirement

- Heat Treatment

- Normalizing, Annealing, Quenching & Tempering

- Flange Types Available

- Slip-On, Weld Neck, Blind, Socket Weld, Threaded, Lap Joint, Orifice

- End Connection

- Butt Weld, Socket Weld, Threaded

- Face Type

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

About ASTM A181 Flanges

What Are Specification ASTM A181 Flanges?

| ASME B16.5 size range | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

Chemical Composition Of ASTM A181 Flanges?

ELEMENT | COMPOSITION, % |

|---|---|

Carbon | 0.35 max |

Manganese | 0.60-1.05 |

Phosphorus | 0.035 max |

Sulfur | 0.040 max |

Silicon | 0.10-0.35 |

Copper | 0.40 max (1) |

Nickel | 0.40 max (1) |

Chromium | 0.30 max (1-2) |

Molybdenum | 0.12 max (1-2) |

Vanadium | 0.08 max |

Mechanical Properties Of ASTM A181 Flanges?

Mechanical Properties | Requirements |

|---|---|

Tensile strength,min,psi [MPa] | 70000 [485] |

Yield strength,min,psi [MPa] | 36000 [250] |

Elongation, min, % | 30 |

Reductionofarea,min,% | 30 |

Hardness,HB,max | 187 |

Comprehensive Range of Flange Types

ASTM A181 flanges are available in a variety of types: slip-on, weld neck, blind, socket weld, threaded, lap joint, and orifice. Each type suits different pipeline configurations and requirements, making them highly versatile for complex industrial installations. Users can choose specific flange facesRF, FF, or RTJto match application needs and ensure secure, leak-free connections.

Superior Material and Strength

Manufactured from durable carbon steel, these flanges undergo rigorous heat treatments such as normalizing, annealing, and quenching & tempering. This enhances their mechanical properties, resulting in high strength, corrosion resistance, and long-term reliability even under high-pressure conditions.

Customizable Dimensions and Pressure Ratings

Clients can order ASTM A181 flanges in a range of sizes and pressure classesfrom Class 60 up to Class 2500tailored according to ANSI/ASME B16.5 standards or specific project drawings. This adaptability allows for precise integration into varied industrial systems, ensuring optimal functionality and safety in every application.

FAQs of ASTM A181 Flanges:

Q: How are ASTM A181 flanges typically used in industrial applications?

A: ASTM A181 flanges are commonly employed to connect pipes, valves, pumps, and other equipment within high-pressure systems in industries like oil & gas, petrochemicals, power plants, and shipbuilding. Their robust design and range of types accommodate diverse installation requirements where dependable leak-proof connections are essential.Q: What flange types and face finishes are available with ASTM A181 flanges?

A: These flanges can be supplied as slip-on, weld neck, blind, socket weld, threaded, lap joint, or orifice types. Available face finishes include Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ), allowing for compatibility with various piping designs and sealing needs.Q: When should I choose a specific heat treatment for A181 flanges?

A: The choice of heat treatmentnormalizing, annealing, quenching, or temperingdepends on the desired mechanical properties and service environment. For example, quenching and tempering enhance strength and durability for high-pressure settings, while annealing provides improved ductility for easier installation.Q: Where are ASTM A181 flanges commonly sourced or manufactured?

A: These flanges are widely manufactured and exported from India by reputed suppliers, manufacturers, and traders. They are available worldwide, catering to global industrial and infrastructure projects wherever robust pipe connections are required.Q: What benefits do ASTM A181 flanges offer over other types of flanges?

A: ASTM A181 flanges deliver excellent corrosion resistance, high mechanical strength, and precise dimensions, making them ideal for demanding and critical service conditions. Their compatibility with high-pressure ratings and customizable configurations adds to their reliability and effectiveness in industrial systems.Q: How does the packaging ensure the safety of ASTM A181 flanges during transit?

A: Flanges are securely packed in wooden boxes, pallets, or customized packaging solutions that prevent damage, protect against moisture, and maintain the integrity of precision machined surfaces during shipping and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Steel Flanges Category

ASTM A350 Lf2 Flanges

Grade : LF2

Material : Carbon Steel

Surface : Other, Rust Proof Oil Coated

Size : 1/2 Inch to 48 Inch

Standard : Other, ASTM A350 Lf2

ASTM A694 Flanges

Grade : F42, F46, F48, F50, F52, F56, F60, F65, F70

Material : Carbon Steel

Surface : Other, Black or Galvanized or Antirust Oil Coating

Size : 1/2 to 48 (DN15 to DN1200)

Standard : Other, ASTM A694

ASTM A105 Forged Steel Flanges

Minimum Order Quantity : 50 Kilograms

Grade : Multple Grades Available

Material : Stainless Steel

Surface : Galvanized

Size : Various Sizes Available

Standard : ANSI

Carbon Steel Round Flanges

Minimum Order Quantity : 50 Kilograms

Grade : Multple Grades Available

Material : Stainless Steel

Surface : Galvanized

Size : Various Sizes Available

Standard : ANSI

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese