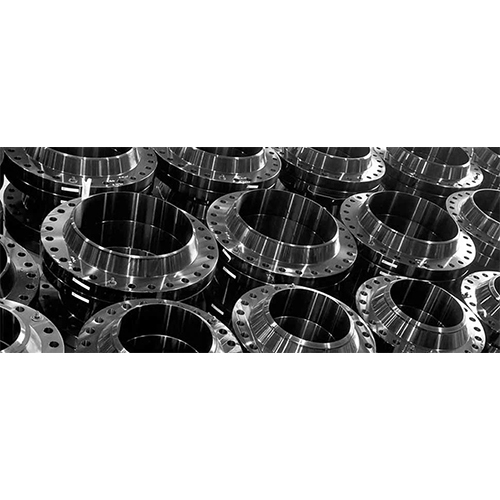

ASTM A694 Flanges

ASTM A694 Flanges Specification

- Feature

- High Strength, Corrosion Resistance, Durable

- Grade

- F42, F46, F48, F50, F52, F56, F60, F65, F70

- Dimension (L*W*H)

- As per standard or customer drawing

- Application

- Oil and Gas, Petrochemical, Power, Water Pipeline, etc.

- Product Type

- Flange

- Material

- Carbon Steel

- Standard

- ASTM A694

- Shape

- Round

- Surface

- Black or Galvanized or Anti-rust Oil Coating

- Connection

- Welded, Threaded, Slip-on, Socket Weld, Blind, Lap Joint, Orifice, Plate

- Technics

- Forged

- Pressure

- Class 150 to Class 2500 (PN20-PN420)

- Size

- 1/2 to 48 (DN15 to DN1200)

- Color

- Black/Grey

- Manufacturing Process

- Heat Treated, Normalized, Quenched and Tempered

- Marking

- Standard, Size, Pressure Class, Material Grade Marked

- Face Type

- RF (Raised Face), FF (Flat Face), RTJ (Ring Type Joint)

- Testing

- Ultrasonic Test, PMI, Hardness, Impact, Hydrostatic

- Packing

- Wooden Cases or Pallets

- End Connection

- ANSI/ASME B16.5, B16.47 Series A & B, MSS SP-44, API-605, DIN, JIS

About ASTM A694 Flanges

What Are Specification ASTM A694 Flanges?

| ASME B16.5 size range | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

Chemical Composition Of ASTM A694 Flanges?

ELEMENT | COMPOSITION, % |

|---|---|

Carbon | 0.35 max |

Manganese | 0.60-1.05 |

Phosphorus | 0.035 max |

Sulfur | 0.040 max |

Silicon | 0.10-0.35 |

Copper | 0.40 max (1) |

Nickel | 0.40 max (1) |

Chromium | 0.30 max (1-2) |

Molybdenum | 0.12 max (1-2) |

Vanadium | 0.08 max |

Mechanical Properties Of ASTM A694 Flanges?

Mechanical Properties | Requirements |

|---|---|

Tensile strength,min,psi [MPa] | 70000 [485] |

Yield strength,min,psi [MPa] | 36000 [250] |

Elongation, min, % | 30 |

Reductionofarea,min,% | 30 |

Hardness,HB,max | 187 |

High-Performance Flanges for Critical Applications

ASTM A694 flanges are favored for their exceptional strength and resistance to corrosion, making them ideal for high-pressure environments. Produced through precision forging and rigorous heat treatment, these flanges are engineered for reliability and extended service life, addressing the demands of pipelines in sectors such as oil and gas, petrochemical, and power.

Versatile Connection and Surface Options

Available with end connections conforming to ANSI/ASME, MSS SP-44, API-605, and international standards like DIN and JIS, these flanges suit a wide range of installation requirements. Customers can choose between surfaces like black, galvanized, or anti-rust oil coatings, with connection types including welded, threaded, slip-on, socket weld, blind, lap joint, orifice, and plate, ensuring compatibility and protection.

FAQs of ASTM A694 Flanges:

Q: How are ASTM A694 flanges manufactured to ensure high strength and durability?

A: ASTM A694 flanges are produced using forging processes followed by heat treatments such as normalizing, quenching, and tempering. These steps enhance the flanges grain structure, resulting in high mechanical strength, improved ductility, and resistance to harsh operating conditions.Q: What face types are available for ASTM A694 flanges and how do they affect usage?

A: ASTM A694 flanges are available in Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ) configurations. Each face type is designed for specific purposes: RF is widely used for general service, FF is suited for flat gasket applications, and RTJ is preferred for high-pressure, leak-tight sealing.Q: When should I select a specific pressure class or grade for these flanges?

A: Selection depends on operating pressure, temperature, and medium. ASTM A694 flanges are available in pressure classes from Class 150 up to Class 2500 (PN20PN420) and in grades F42 to F70. Choose the pressure class and grade based on your pipelines design requirements and applicable industry standards.Q: Where can ASTM A694 flanges be applied, and what industries benefit most from their usage?

A: These flanges are widely used in oil and gas, petrochemical, power generation, and water pipeline projects due to their high strength, toughness, and ability to withstand aggressive media and elevated pressures.Q: What testing and quality checks are performed on ASTM A694 flanges?

A: Each flange undergoes comprehensive tests including ultrasonic examination, Positive Material Identification (PMI), hardness and impact testing, and hydrostatic testing. These procedures confirm material integrity, chemical composition, mechanical properties, and pressure-holding capacity.Q: How are ASTM A694 flanges packed, marked, and shipped?

A: Flanges are typically packed in sturdy wooden cases or palletized for safe transportation. Markings include standard details, size, pressure class, material grade, and other specifications per industry standards, ensuring traceability and compliance on delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Steel Flanges Category

ASTM A181 Flanges

Surface : Other, Rust Proof

Size : Customizable

Grade : Class 60, Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, Class 2500

Purity : Standard commercial grade

Standard : Other, ASTM A181

ASTM A350 Lf2 Flanges

Surface : Other, Rust Proof Oil Coated

Size : 1/2 Inch to 48 Inch

Grade : LF2

Purity : 99%

Standard : Other, ASTM A350 Lf2

ASTM A105 Forged Steel Flanges

Minimum Order Quantity : 50 Kilograms

Surface : Galvanized

Size : Various Sizes Available

Grade : Multple Grades Available

Purity : 8099%

Standard : ANSI

Carbon Steel Round Flanges

Minimum Order Quantity : 50 Kilograms

Surface : Galvanized

Size : Various Sizes Available

Grade : Multple Grades Available

Purity : 8099%

Standard : ANSI

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese