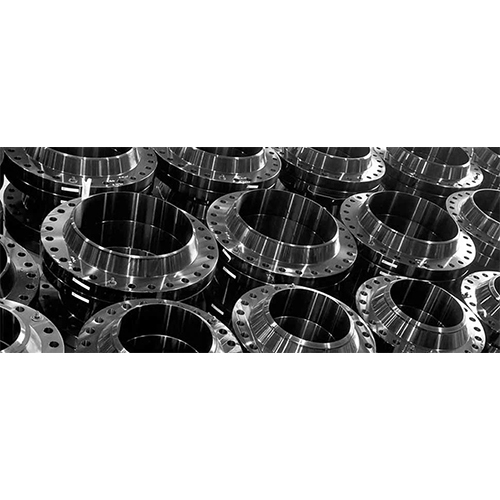

ASTM A350 Lf2 Flanges

ASTM A350 Lf2 Flanges Specification

- Grade

- LF2

- Application

- Oil & Gas, Petrochemical, Power Plants, Marine, Chemical Industry

- Dimension (L*W*H)

- As per ASME/ANSI B16.5, B16.47 or Customized

- Purity

- 99%

- Feature

- High Strength, Accurate Dimension, Corrosion Resistant

- Product Type

- Industrial Flange

- Material

- Carbon Steel

- Standard

- ASTM A350 Lf2

- Shape

- Round

- Surface

- Rust Proof Oil Coated

- Connection

- Welded/Threaded/Bolted

- Technics

- Forged

- Pressure

- Class 150 to 2500

- Size

- 1/2 Inch to 48 Inch

- Color

- Silver / Grey

- Packaging

- Wooden Cases/Pallets or as per customer requirement

- Types Available

- Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint, Orifice Flange

- Yield Strength

- 250 MPa (min)

- Face Type

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Hardness

- 163 HB Max

- End Connection

- Butt Weld, Socket Weld, Threaded

- Impact Test

- Charpy V-Notch Tested at -46°C

- Temperature Range

- -46°C to 345°C (-50°F to 650°F)

- Manufacturing Standard

- ASME B16.5, B16.47, API 6A

- Tensile Strength

- 485 MPa (min)

About ASTM A350 Lf2 Flanges

What Are Specification ASTM A350 Lf2 Flanges?

| ASME B16.5 size range | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

Chemical Composition Of ASTM A350 Lf2 Flanges?

ELEMENT | COMPOSITION, % |

|---|---|

Carbon | 0.35 max |

Manganese | 0.60-1.05 |

Phosphorus | 0.035 max |

Sulfur | 0.040 max |

Silicon | 0.10-0.35 |

Copper | 0.40 max (1) |

Nickel | 0.40 max (1) |

Chromium | 0.30 max (1-2) |

Molybdenum | 0.12 max (1-2) |

Vanadium | 0.08 max |

Mechanical Properties Of ASTM A350 Lf2 Flanges?

Mechanical Properties | Requirements |

|---|---|

Tensile strength,min,psi [MPa] | 70000 [485] |

Yield strength,min,psi [MPa] | 36000 [250] |

Elongation, min, % | 30 |

Reductionofarea,min,% | 30 |

Hardness,HB,max | 187 |

Versatile Face Types & Connections

ASTM A350 LF2 flanges offer flexibility with face options like Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ), adaptable to varied piping requirements. Their end connections include butt weld, socket weld, and threaded, ensuring compatibility with diverse installation methods. This adaptability makes them a great fit for rigorous industrial environments.

Manufactured to Strict Standards

Conforming to ASME B16.5, B16.47, and API 6A, LF2 flanges guarantee quality and spec compliance for global applications. Each flange undergoes impact (Charpy V-Notch) testing at -46C, with tensile and yield strengths of 485 MPa and 250 MPa minimum. The use of forged carbon steel ensures high strength and durability in challenging conditions.

Reliable Performance Across Temperatures

With a temperature range of -46C to 345C, these flanges deliver consistent strength and resilience, even in sub-zero environments. Their corrosion-resistant, oil-coated surfaces provide long-lasting reliability. This makes LF2 flanges a preferred choice in industries where temperature fluctuations demand stable mechanical properties.

FAQs of ASTM A350 Lf2 Flanges:

Q: How are ASTM A350 LF2 flanges tested for low-temperature applications?

A: These flanges undergo a Charpy V-Notch impact test at -46C, ensuring they provide reliable toughness and resistance to brittle fracture in low-temperature service environments.Q: What types of face finishes are available for LF2 flanges and when should each be used?

A: LF2 flanges come in Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ) finishes. RF is ideal for high-pressure environments, FF is used for lower pressure or cast iron equipment, and RTJ is preferred for high-pressure, leak-tight service.Q: Where can ASTM A350 LF2 flanges be applied?

A: These flanges are commonly used in oil & gas, petrochemical, power plants, marine, and chemical industries where robust mechanical performance and corrosion resistance are essential.Q: What is the manufacturing process for ASTM A350 LF2 flanges?

A: LF2 flanges are typically produced using forging techniques, followed by precision machining to attain accurate dimensions and meet ASME/ANSI B16.5, B16.47 standards.Q: How do the strength and hardness specifications benefit LF2 flange users?

A: With a minimum tensile strength of 485 MPa and hardness up to 163 HB, these flanges ensure high durability, safety, and longevity under demanding conditions.Q: What is the standard packaging for ASTM A350 LF2 flanges?

A: Flanges are usually packed in wooden cases or pallets, but packaging can be customized as per customer requirements to ensure safe transport and storage.Q: Why are oil-coated surfaces important for LF2 flanges?

A: The rust-proof oil coating protects the carbon steel from corrosion during storage and transit, maintaining the flanges integrity until installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Steel Flanges Category

ASTM A181 Flanges

Grade : Class 60, Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, Class 2500

Standard : Other, ASTM A181

Technics : Other, Forged

Size : Customizable

Surface : Other, Rust Proof

ASTM A694 Flanges

Grade : F42, F46, F48, F50, F52, F56, F60, F65, F70

Standard : Other, ASTM A694

Technics : Other, Forged

Size : 1/2 to 48 (DN15 to DN1200)

Surface : Other, Black or Galvanized or Antirust Oil Coating

Carbon Steel Round Flanges

Minimum Order Quantity : 50 Kilograms

Grade : Multple Grades Available

Standard : ANSI

Technics : Hot Rolled

Size : Various Sizes Available

Surface : Galvanized

ASTM A105 Forged Steel Flanges

Minimum Order Quantity : 50 Kilograms

Grade : Multple Grades Available

Standard : ANSI

Technics : Hot Rolled

Size : Various Sizes Available

Surface : Galvanized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese