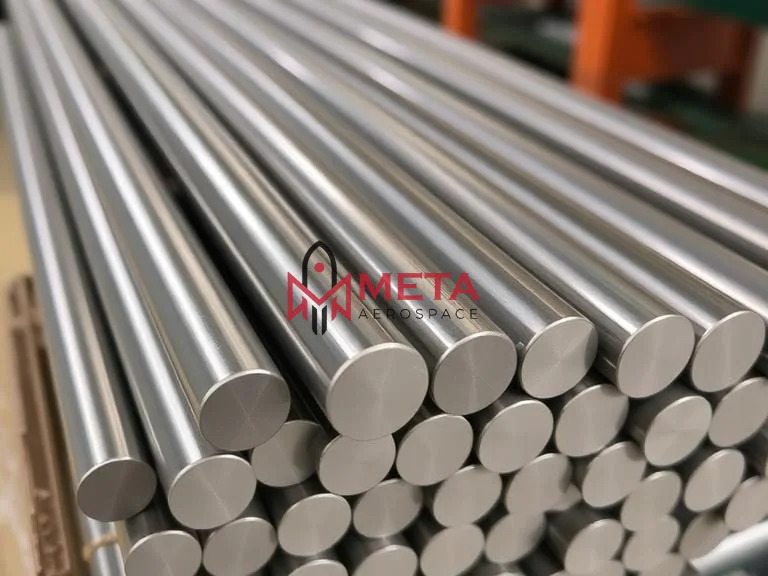

Nitronic 60 Round Bars

Nitronic 60 Round Bars Specification

- Material Composition %

- Cr 17%, Ni 8.5%, Mn 8%, Si 4%, N 0.15%

- Heat Resistance

- Yes

- Coating Type

- Uncoated / As Requested

- Recyclable

- Yes

- Hardness

- Rockwell B 95-100

- Tensile Strength

- 90 ksi (Minimum)

- Corrosion Resistant

- Excellent

- Size

- Customized/Standard Sizes as Required

- Product Form

- Solid Round Bar

- Diameter

- 8 mm to 200 mm

- Product Name

- Nitronic 60 Round Bars

- Steel Type

- Austenitic Stainless Steel

- Steel Product Type

- Round Bar

- Grade

- Nitronic 60 (UNS S21800)

- Thickness

- As Required (per Diameter Specification)

- Shape

- Round

- Steel Standard

- ASTM, ASME, EN, JIS

- Surface

- Bright, Polished, Peeled, Turned, Black

- Composition

- Cr 16-18%, Ni 8-9%, Mn 7-9%, Si 3.5-4.5%, N 0.08-0.18%

- Application

- Construction, Valve Stems, Pump Shafts, Fasteners, Marine, Petrochemical, Food Processing Industries

- Dimension (L*W*H)

- Customizable as per requirement

- Weight

- Varies With Size & Length

- Color

- Metallic Silver

- Material Grade

- Nitronic 60

- Finish Type

- Polished, Peeled, Black, Bright

- Usage

- Engineering, Chemical Processing, Paper Mills, Marine

- Density

- 7.8 g/cm

- Machinability

- Good with High Wear Resistance

- Magnetic Permeability

- Non-magnetic in Annealed Condition

- Resistance Features

- Excellent Galling & Wear Resistance

- Elongation

- 35% (minimium)

- Minimum Order Quantity

- As per Customer Requirement

- Yield Strength

- 50 ksi (Minimum)

- Standards Compliance

- ASTM A276, ASTM A479

- Processing Type

- Cold Drawn/Hot Rolled

- Available Lengths

- 1 Meter, 2 Meter, 3 Meter, or Custom Cut Lengths

About Nitronic 60 Round Bars

What Are Specification Nitronic 60 Round Bars?

| Stainless Steel Round Bar type | Nitronic 50 stainless steel round bars |

|---|---|

| Standards | A276, A479, A276, GB4226-84, GB/T1220-2007, JISG4311-91, JIS G4318-98, EN 10095-99, GB4226-84, EN10088-3-2005, JIS G904L3-2005, etc |

| Range | Range 3.17mm to 350mm dia |

| Diameter | 2.0-400mm |

| Length | 3000mm, 6000mm or according to the customers requirement. |

| Type | Round bar, rod, square bar, flat bar, hexagon bar, angle bar, channel bar, threaded bar |

| Technique | Forged/Hot Rolled/Cold Drawn/Peeled |

| Surface | bright round bar, pickled round bar, black round bar |

| Package Details | Standard seaworthy package(wooden boxes package,pvc package, or other package) |

| Export Area | USA, UAE, Europe, Asia, Middle East, Africa, South America |

Equivalent material Of Nitronic 60 Round Bars?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Nitronic 60 | 1.3964 | S21800 |

Chemical Composition Of Nitronic 60 Round Bars?

| Grade | C | Mn | Si | S | Mo | Cr | Ni |

|---|---|---|---|---|---|---|---|

| Nitronic 60 | 0.06 max | 4-6 | 1 max | 0.03 max | 1.5-3 | 20.5-23.5 | 11.5-13.5 |

Mechanical Properties Of Nitronic 60 Round Bars?

| Element | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| Nitronic 60 | 7.8 g/cm3 | Psi 100000, MPa 689 | Psi 55000, MPa 379 | 35 % |

Superior Wear and Galling Resistance

Nitronic 60 Round Bars stand out for their excellent resistance to galling and wear, ensuring long-term durability in challenging operating environments. Their unique composition guarantees reliable performance in heavy-duty applications, making them suitable for valve stems, pump shafts, and fasteners exposed to severe wear conditions.

Versatile Applications Across Industries

Engineered for versatility, Nitronic 60 Round Bars are suitable for use in a variety of industries including construction, marine, petrochemical, food processing, paper mills, and chemical processing. Their excellent corrosion, heat, and wear resistance make them a preferred choice in situations requiring robust and long-lasting materials.

Customizable to Project Needs

With the option for custom-cut lengths, diameters ranging from 8 mm to 200 mm, and a range of surface finishes, these round bars are fully adaptable to specific project requirements. Minimum order quantity is flexible to suit customer needs, and products can be tailored for both small-scale and large industrial applications.

FAQs of Nitronic 60 Round Bars:

Q: How are Nitronic 60 Round Bars processed and finished?

A: Nitronic 60 Round Bars are manufactured using cold drawing or hot rolling methods, depending on the desired mechanical properties and size specifications. They are available with various surface finishes including polished, bright, peeled, black, and turned, ensuring both aesthetic and functional requirements are met.Q: What applications benefit most from Nitronic 60 Round Bars?

A: These round bars are ideal for use in valve stems, pump shafts, fasteners, construction, marine, petrochemical, food processing, chemical processing, and paper mill industries. Their exceptional resistance to wear, galling, corrosion, and heat makes them especially suitable for demanding environments.Q: When should I choose Nitronic 60 over other stainless steel grades?

A: Select Nitronic 60 when high wear and galling resistance are critical, and where good machinability and non-magnetic properties in the annealed condition are required. It is particularly advantageous for moving parts and contact surfaces subjected to friction and where superior corrosion resistance is needed.Q: Where can Nitronic 60 Round Bars be supplied from and to?

A: Nitronic 60 Round Bars are exported, manufactured, and supplied by leading exporters, manufacturers, suppliers, and traders across India, with the capability to ship internationally as per customer requirements.Q: What are the key benefits of using Nitronic 60 Round Bars?

A: Key advantages include excellent resistance to galling, wear, and corrosion, high elongation and strength, good machinability, non-magnetic properties in the annealed state, and adaptability to custom sizes and lengths.Q: How are sizes and lengths of Nitronic 60 Round Bars customized?

A: Bars are available in standard lengths (1, 2, and 3 meters) as well as custom-cut sizes based on client specifications. Diameter range is from 8 mm to 200 mm, and both size and length can be tailored to fit project needs.Q: What standards and specifications do Nitronic 60 Round Bars meet?

A: They meet or exceed ASTM A276 and ASTM A479 standards, and can conform to additional international standards such as ASME, EN, and JIS upon request.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Bars Category

Stainless Steel 15-5 PH Round Bars

Recyclable : Yes

Color : Silver / Metallic

Finish Type : Bright, Polished, Peeled

Steel Type : Stainless Steel

Heat Resistance : Yes

Composition : Fe, 15% Cr, 5% Ni, 3.5% Cu, 0.07% C, balance other elements

Stainless Steel 347H Round Bars

Recyclable : Yes

Color : Silver

Finish Type : Bright, Polish, Black

Steel Type : Other, Austenitic Stainless Steel

Heat Resistance : Yes

Composition : Stainless Steel 347H (Fe, C, Cr, Ni, Si, Mn, S, P, Nb)

Nitronic 50-XM 19 Round Bars

Recyclable : Yes

Color : Silver/Grey

Finish Type : Bright, Black, Polished

Steel Type : Other, Austenitic Stainless Steel

Heat Resistance : Yes

Composition : Fe, Cr, Ni, Mn, Mo, Si, N, C

Stainless Steel 316Ti Round Bars

Recyclable : Yes

Color : Silver / Metallic

Finish Type : Polished / Bright / Black

Steel Type : Stainless Steel

Heat Resistance : Yes

Composition : CrNiMoTi Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese