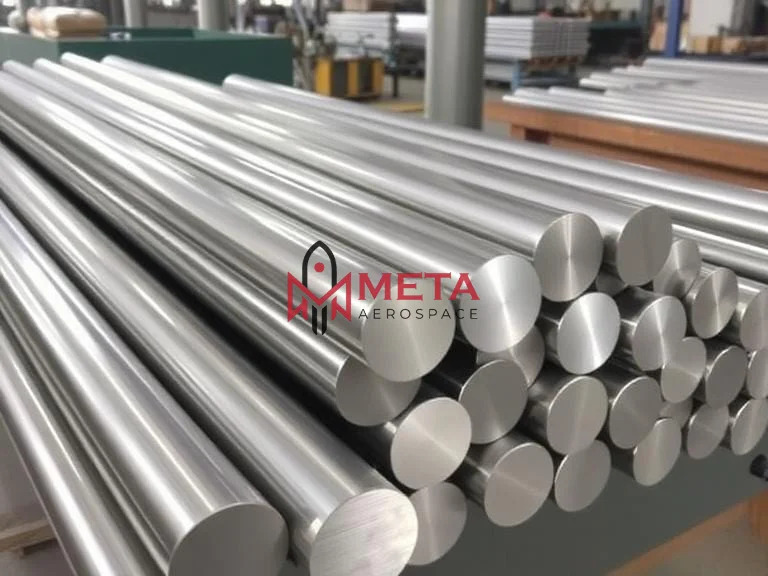

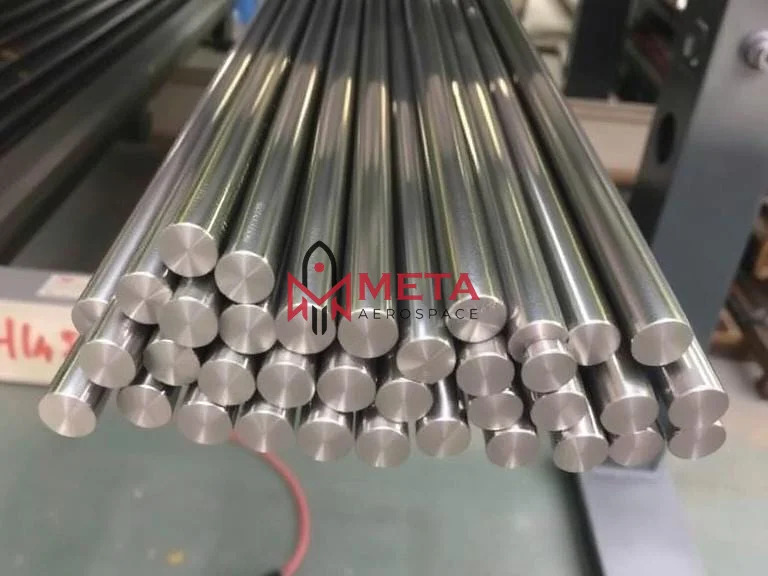

Stainless Steel 17-7 PH Round Bars

Stainless Steel 17-7 PH Round Bars Specification

- Product Form

- Bars/Rods

- Tensile Strength

- Up to 1310 MPa

- Size

- Cut-to-size as per order

- Corrosion Resistant

- Excellent

- Diameter

- 3 mm to 200 mm (custom size available)

- Material Composition %

- Cr 16-18%, Ni 6.50-7.75%, Al 0.75-1.50%, C 0.09%, Mn 1.00%, Si 1.00%, P 0.040%, S 0.030%, Fe balance

- Recyclable

- Yes

- Hardness

- Rockwell C 38-45 (after heat treatment)

- Coating Type

- Uncoated / As rolled

- Heat Resistance

- Yes

- Product Name

- Stainless Steel 17-7 PH Round Bars

- Steel Type

- Stainless Steel

- Steel Product Type

- Round Bar

- Grade

- 17-7 PH

- Thickness

- 0.5 mm to 100 mm (or as per requirement)

- Shape

- Round

- Steel Standard

- ASTM A564, AMS 5644, EN, JIS Standards

- Surface

- Bright, Polished, Peeled, Turned

- Composition

- Chromium, Nickel, Aluminum, Iron, trace elements

- Application

- Aerospace, Chemical Processing, Industrial Engineering, Springs, Fasteners, Structural Components

- Dimension (L*W*H)

- Customizable as per requirement

- Weight

- Varies as per size and length

- Color

- Silver/Grey

- Material Grade

- 17-7 PH (UNS S17700)

- Finish Type

- Bright/Polished

- Usage

- Springs, washers, diaphragms, high strength parts

- Minimum Order Quantity

- Negotiable

- Machinability

- Good after solution treatment

- Packing

- Export standard sea-worthy packaging

- Delivery Condition

- Solution Annealed, Precipitation Hardened

- Elongation

- 6% (at break)

- Magnetic Properties

- Magnetic in conditions after cold working

- Yield Strength

- Up to 1170 MPa

About Stainless Steel 17-7 PH Round Bars

What Are Specification Stainless Steel 17-7 PH Round Bars?

| Specification : | ASTM A564 / ASME SA564 |

|---|---|

| Standard : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round Bars : | Outside Diameter in the range of 4mm to 500mm |

| Hex Bar size : | 2-100mm A/F |

| Bright Bars : | Outside Diameter in the range of 4mm to 100mm |

| Hex Bars : | 18mm 57mm (11/16 to 2-3/4) |

| Square Bars : | 18mm 47mm (11/16 to 1-3/4) |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length : | 1 to 6 Meters, Custom Cut Lengths |

| Form : | Round, Square, Hex (A/F), Rectangle Etc. |

Equivalent material Of Stainless Steel 17-7 PH Round Bars?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| SS 17-7 PH | - | S17700 |

Chemical Composition Of Stainless Steel 17-7 PH Round Bars?

| Grade | C | P | Si | Ni | Cu | Fe | Mn | S | Cr | AL |

|---|---|---|---|---|---|---|---|---|---|---|

| SS 17-7 PH | .09 | .04 | 1.0 max | 6.50 - 7.75 | - | Bal | 1.0 max | 0.04 | 16.0 - 18.0 | .75 - 1.50 |

Mechanical Properties Of Stainless Steel 17-7 PH Round Bars?

| Grade | Tensile Strength | Yield Strength | Modulus of Elasticity | Poissons Ration | Elongation at Break | Hardness, Rockwell C |

|---|---|---|---|---|---|---|

| 17-7 PH | 170000 psi | 140000 psi | 29600 ksi | 0.27 0.30 | 6% | 38 |

High Performance for Demanding Industries

Stainless Steel 17-7 PH Round Bars are trusted in critical fields such as aerospace, chemical processing, and industrial engineering. Their superior tensile and yield strength, combined with excellent heat and corrosion resistance, make them suitable for high-stress environments. Compliance with international standards assures reliability and safety, while their magnetic properties post-cold working add versatility.

Custom Dimensions and Finishes Available

Manufactured in a variety of thicknesses and diameters, these round bars are available in bright polished, peeled, or turned finishes to suit specific project needs. Clients can request sizes cut to order, ensuring the product integrates seamlessly into applications like springs, washers, and structural components. Export-standard, sea-worthy packaging guarantees product integrity during shipment.

FAQs of Stainless Steel 17-7 PH Round Bars:

Q: How is the Stainless Steel 17-7 PH Round Bar delivered and packed for export?

A: These round bars are delivered in a solution annealed and precipitation hardened condition. Packing is conducted using export standard, sea-worthy materials to ensure safe transit and protection from environmental factors, enabling reliable global delivery.Q: What applications are Stainless Steel 17-7 PH Round Bars commonly used for?

A: Thanks to their high strength, corrosion resistance, and good machinability, these bars are extensively used in aerospace, chemical processing, industrial engineering, springs, fasteners, washers, diaphragms, and high-strength structural components.Q: When is the machinability of these bars considered optimal?

A: Machinability is considered good after solution treatment when the bar structure is softened, allowing easier shaping and machining into desired components before precipitation hardening is performed for additional strengthening.Q: Where do the magnetic properties of Stainless Steel 17-7 PH Round Bars become evident?

A: The bars exhibit magnetic properties after cold working, which makes them functional in applications requiring temporary or permanent magnetism, such as certain mechanical or structural components.Q: What is the process for customizing the size and shape of these round bars?

A: Customers can specify dimensions including thickness (0.5 mm to 100 mm) and diameter (3 mm to 200 mm) as per their requirements. The manufacturer offers cut-to-size options and can accommodate unique shapes for specific applications upon request.Q: How does the composition contribute to the bars performance and corrosion resistance?

A: The alloy comprises chromium (16-18%), nickel (6.50-7.75%), and aluminum (0.75-1.50%) along with iron and trace elements, providing excellent durability and resistance to corrosion, especially in demanding chemical and industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Bars Category

Stainless Steel 347H Round Bars

Usage : Industrial, Fabrication, Piping, Shafts, General Engineering

Thickness : Available in multiple thicknesses (as per order)

Recyclable : Yes

Composition : Stainless Steel 347H (Fe, C, Cr, Ni, Si, Mn, S, P, Nb)

Hardness : Rockwell B95 max

Product Name : Other, Stainless Steel 347H Round Bars

Stainless Steel 316Ti Round Bars

Usage : Structural, Machined Parts, Fasteners, Shafts, Pipelines

Thickness : Ranges from 3 mm and above

Recyclable : Yes

Composition : CrNiMoTi Stainless Steel

Hardness : HRB 95 max

Product Name : Other, Stainless Steel 316Ti Round Bars

Stainless Steel 321H Round Bars

Usage : For fabrication in high temperature environments

Thickness : 10 mm to 300 mm

Recyclable : Yes

Composition : ChromiumNickel with Titanium addition

Hardness : 217 HB

Product Name : Other, Stainless Steel 321H Round Bars

Nitronic 50-XM 19 Round Bars

Usage : Engineering, Structural, Machining, Fabrication

Thickness : Varies (Standard: 3mm to 300mm)

Recyclable : Yes

Composition : Fe, Cr, Ni, Mn, Mo, Si, N, C

Hardness : Rockwell B95 (max)

Product Name : Other, Nitronic 50XM 19 Round Bars

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese