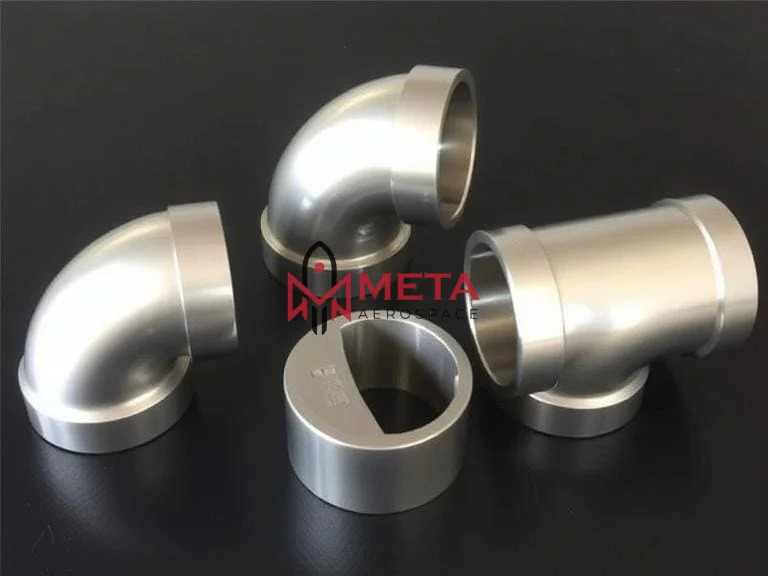

Stainless Steel 310310S Pipe Fittings

Stainless Steel 310310S Pipe Fittings Specification

- Temperature Range

- Up to 1150C (2102F)

- Thread Type

- NPT/BSP (for threaded fittings)

- Tensile Strength

- 520 MPa min

- Yield Strength

- 205 MPa min

- Bend Radius

- Standard as per fitting type

- Diameter

- Nominal sizes 1/2 to 24

- Sealing Type

- Metal-to-Metal

- Coating Type

- Uncoated/Natural

- Tolerance

- 0.5 mm

- Connection Type

- Welded / Threaded / Flanged

- Flexibility

- Rigid

- Product Type

- Pipe Fittings

- Material

- Stainless Steel 310/310S

- Connection

- Butt Weld / Socket Weld / Threaded

- Shape

- Elbow, Tee, Reducer, Stub End, Cap, Cross

- Standard

- ASTM A403 / ASME SA403

- Surface Treatment

- Pickled, Annealed

- Outer Diameter

- 1/2 (21.34 mm) to 24 (609.6 mm)

- Section Shape

- Round

- Length

- Up to 18 inches (varies by fitting type)

- Thickness

- 1.5 mm to 20 mm

- Color

- Silver/Grey

- Usage

- Industrial Piping, Petrochemical, Power Plant, High-Temperature Service

- Rated Pressure

- SCH 10S to SCH XXS

- Material Grade

- SS 310 / SS 310S

- Application

- Chemical Processing, Heat Exchangers, Furnace Parts

- Form

- Seamless and Welded

- End Type

- Beveled, Plain, Threaded Ends

- Hardness

- 217 HB max

- Heat Treatment

- Solution Annealed (1040C 1150C)

- Corrosion Resistance

- Excellent in oxidizing atmospheres

- Standards Compliance

- DIN, EN, ISO, JIS (on request)

- Density

- 7.9 g/cm

- Magnetism

- Non-magnetic in annealed condition

About Stainless Steel 310310S Pipe Fittings

What Are Specification Stainless Steel 310/310S Pipe Fittings?

| Standards : | ASTM, ASME |

|---|---|

| Designation : | A 403, SA 403 |

| Dimension Standard : | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Grade : | Stainless Steel 304L Buttweld Pipe Fittings, SS 304L Butt weld |

| Type : | Seamless, Welded |

| Thickness : | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS |

| Size : | 1/2" to 24" |

| Two Joint / Two Halve 304 Butt weld Fittings Size : | 6" to 48" |

| Types of Butt weld Fittings : | Equal Tee, Nipple, Long Radius Elbow, Reducing Tee, Elbows, Swage Nipple, Short Radius Elbow, Reducer, Barrel Nipple, 90 Deg Elbow, Concentric Reducer, Reducing Nipple, 45 Deg Elbows, Eccentric Reducer, Bend, 180 Deg Elbow, End Cap, 1D Elbow, 3D Elbow, Stubend, 5D Elbow, Cap, Piggable Bend, Long Stubend, Tee, Short Stubend, Long Radius Bend |

Equivalent material Of Stainless Steel 310/310S Pipe Fittings?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | X15CrNi25-20 | |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | X8CrNi25-21 |

Chemical Composition Of Stainless Steel 310/310S Pipe Fittings?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 26.00 | 0.10 max | 19.00 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 26.00 | 0.75 max | 19.00 21.00 | 53.095 min |

Mechanical Properties Of Stainless Steel 310/310S Pipe Fittings?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 C (2555 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

Outstanding Performance in High Temperatures

Engineered for resilience, Stainless Steel 310/310S pipe fittings can withstand continuous service up to 1150C (2102F). Their superior heat resistance makes them essential for furnace components, heat exchangers, and industrial piping systems exposed to elevated temperatures.

Versatile Shapes and Connection Types

These fittings are available in a diverse range of shapes including elbows, tees, reducers, stub ends, caps, and crosses, with connection types such as butt weld, socket weld, and threaded options (NPT/BSP). This flexibility allows for easy integration into various piping designs and replacement needs.

Compliance and Quality Assurance

Manufactured in strict accordance with ASTM A403/ASME SA403 and available with DIN, EN, ISO, or JIS compliance upon request, each fitting undergoes solution annealing for optimum mechanical properties. Tolerances are maintained within 0.5 mm and pressure ratings range from SCH 10S to SCH XXS.

FAQs of Stainless Steel 310310S Pipe Fittings:

Q: How do Stainless Steel 310/310S pipe fittings resist corrosion in high-temperature environments?

A: These fittings exhibit excellent corrosion resistance, particularly in oxidizing atmospheres, due to their elevated chromium and nickel content. Their solution annealed and pickled surfaces further enhance durability, making them ideal for industrial environments prone to oxidation and scaling.Q: What standards do SS 310/310S pipe fittings comply with, and can they be customized for specific requirements?

A: SS 310/310S pipe fittings are manufactured under ASTM A403 and ASME SA403 standards. On request, fittings can also be supplied with DIN, EN, ISO, or JIS compliance to meet specific project needs, ensuring they are suitable for global industrial applications.Q: When should seamless versus welded pipe fittings be used?

A: Seamless fittings offer superior strength and are preferred for critical, high-pressure applications, whereas welded fittings are more economical and suitable for standard industrial piping with moderate pressures and temperatures. Choice depends on system requirements and safety standards.Q: Where are Stainless Steel 310/310S pipe fittings commonly used?

A: These fittings are widely used in chemical processing, petrochemical industries, power generation plants, heat exchangers, and furnace parts due to their ability to handle high temperatures and corrosive substances.Q: What is the process for heat treating SS 310/310S pipe fittings?

A: All fittings are solution annealed between 1040C and 1150C, followed by rapid cooling. This process ensures optimal mechanical properties, maintains the non-magnetic condition, and increases ductility and corrosion resistance.Q: How does the design ensure a secure and leak-proof connection?

A: Stainless Steel 310/310S fittings utilize metal-to-metal sealing and can be supplied in beveled, plain, or threaded ends, which, in conjunction with precise dimensional tolerances (0.5 mm), guarantee tight connections for safe, leak-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Pipe Fittings Category

Stainless Steel 317317L Pipe Fittings

Usage : Industrial Piping, Chemical Processing

Surface Treatment : Other, Shot Blasted / Pickled / Polished

Standard : Other, ASTM A403 / ASME SA403

Material : Other , Stainless Steel 317/317L

Material Grade : SS 317/317L

Connection : Other, Welded / Threaded

Stainless Steel 316316L316H Pipe Fittings

Usage : Industrial piping, chemical processing

Surface Treatment : Other, Polished / Pickled / Sand Blasting

Standard : Other, ASTM A403 / ASME SA403

Material : Stainless Steel

Material Grade : 316, 316L, 316H

Connection : Other, Welded / Seamless / Threaded

Stainless Steel 316Ti Pipe Fittings

Usage : Industrial, Plumbing, Chemical Processing

Surface Treatment : Other, Pickled, Passivated

Standard : Other, ASTM A403 / ASME SA403

Material : Stainless Steel

Material Grade : 316Ti

Connection : Other, Welded, Threaded

Stainless Steel 304304L Pipe Fittings

Usage : Piping System, Plumbing, Industrial, Chemical, Petrochemical

Surface Treatment : Other, Polished / Pickled / Annealed

Standard : Other, ASTM A403 / ASME SA403

Material : Other , Stainless Steel 304/304L

Material Grade : 304 / 304L

Connection : Other, Welded / Buttweld / Threaded

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese