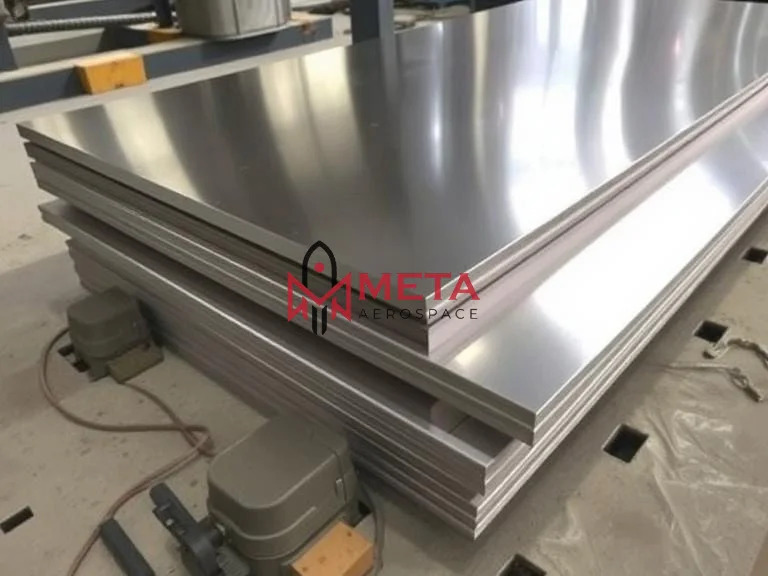

Incoloy 800800H800HT Sheets

Incoloy 800800H800HT Sheets Specification

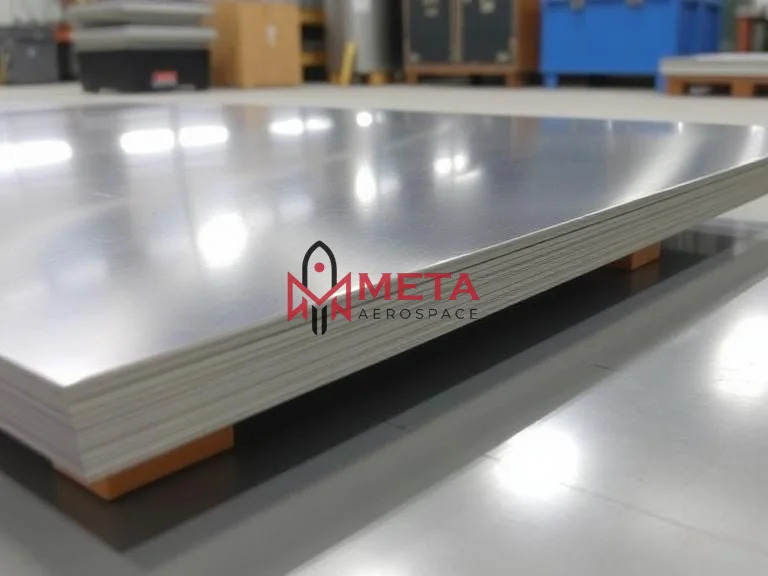

- Thickness

- 0.5 mm to 50 mm

- Thermal Conductivity

- 11.0 W/mK at 25C

- Tensile Strength

- 550 MPa min (for 800), 450 MPa min (for 800H/800HT)

- Product Type

- Sheets

- Types of Alloy

- Nickel-Iron-Chromium Alloy

- Material

- Incoloy 800/800H/800HT

- Shape

- Sheet/Flat

- Strength

- Excellent high temperature strength

- Resistance

- Oxidation, carburization, and corrosion resistance

- Grade

- 800, 800H, 800HT

- Melting Point

- 1357-1385 C

- Density

- 7.94 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Ni 30-35%, Cr 19-23%, Fe balance, Al 0.15-0.60%, Ti 0.15-0.60%, C (800: 0.10%, 800H: 0.05-0.10%, 800HT: 0.06-0.10%)

- Color

- Silvery-grey

- Fabrication

- Good formability and weldability

- Finish

- Hot Rolled, Cold Rolled, 2B, BA, No.1, No.4, Matte, Mirror

- Operating Temperature Range

- up to 1100C

- Microstructure

- Austenitic

- Elongation

- 30% (in 50 mm)

- Width

- up to 2500 mm

- Application

- Thermal processing, chemical and petrochemical processing, power generation, superheaters, heat exchangers

- Yield Strength

- 205 MPa min

- Magnetic Permeability

- 1.03 @ 200 Oe

- Delivery Condition

- Annealed

- Length

- up to 6000 mm or as required

- Surface Treatment

- Bright, Pickled, Polished

- Standard

- ASTM B409, ASME SB409

About Incoloy 800800H800HT Sheets

What Are Specification Incoloy 800/800H/800HT Plates?

| Type | Plate, Sheet, Strip, Flats, Coils, Foils, Clad Plate, Rolls, Blank (Circle), Plain Sheet, Rolling Plate, Flat Sheet, Rolling Sheet, Shim Sheet, Flat Shim, sheared, annealed, descaled, soft annealed, tread plate, Checker Plate |

|---|---|

| ASTM B168 Alloy 800 Plate Length | 0-12mm or as required |

| 800 Inconel Plate Width | 0-2500mm or as required |

| ASTM B168 Alloy 800 Plate Thickness | 0.3 to 1200 mm or as required |

| UNS N06800 Plate Process | Hot/ Cold Rolled |

| Inconel 800 Plate surface | No.1, No.3, No. 2D, BA, No. 2B, No.6, 2B, No.7, No.4, 2D, (CR) Cold rolled sheet , No.1 finish hot rolled, 1D, SATIN (Met with Plastic Coated), ASTM B168 Alloy 800 Plate, No.4, 2B, 8K, BA, (HR) Hot rolled plate , satin, brush, hairline, mirror, BA No(8) etc. |

Equivalent material Of Incoloy 800/800H/800HT Plates?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

|---|---|---|---|---|---|---|---|---|

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | 670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | 670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | 670 | - | X8NiCrAlTi32-21 | XH32T |

Chemical Composition Of Incoloy 800/800H/800HT Plates?

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Incoloy 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30 35 | 19 23 | 0.15 0.60 | 0.15 0.60 |

| Incoloy 800H | 0.05 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30 35 | 19 23 | 0.15 0.60 | 0.15 0.60 |

| Incoloy 800HT | 0.06 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30 35 | 19 23 | 0.15 0.60 | 0.15 0.60 |

Mechanical Properties Of Incoloy 800/800H/800HT Plates?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.94 g/cm3 | 1385 C (2525 F) | Psi 75,000 , MPa 520 | Psi 30,000 , MPa 205 | 30 % |

High-Temperature Strength and Stability

Incoloy 800 series sheets are engineered to maintain high strength and structural integrity even at temperatures up to 1100C. Their carefully balanced microstructure and alloy composition ensure excellent performance in demanding environments such as superheaters, heat exchangers, and power generation systems.

Superior Resistance to Corrosion and Oxidation

These sheets provide outstanding resistance to oxidation, carburization, and corrosion, making them ideal for harsh chemical and petrochemical processing plants. Their silvery-grey surface and various treatment options protect against environmental degradation and extend service life.

Versatile Applications and Finish Options

With a range of finishes including pickled, polished, and mirror, as well as customizable dimensions, Incoloy 800, 800H, and 800HT sheets can be tailored to diverse industrial applications. They are suitable for fabrication projects where ease of forming, welding, and durability are critical considerations.

FAQs of Incoloy 800800H800HT Sheets:

Q: What are the main benefits of using Incoloy 800/800H/800HT sheets in industrial applications?

A: These sheets offer a combination of excellent high-temperature strength, superior resistance to oxidation and corrosion, and stable mechanical properties. They are well-suited for use in thermal processing, power plants, chemical, and petrochemical environments that demand durability and reliability.Q: How is the formability and weldability of Incoloy 800/800H/800HT sheets during fabrication?

A: Incoloy 800 series sheets possess good formability and weldability, making them suitable for various fabrication processes. They can be easily shaped and joined without compromising their structural or mechanical integrity, even under demanding conditions.Q: Where are Incoloy 800 series sheets typically used?

A: These sheets are commonly utilized in the construction of superheaters, heat exchangers, process piping, and reactors in industries such as thermal processing, power generation, chemical, and petrochemical processing, due to their high-temperature and corrosion-resistant properties.Q: What surface finishes and treatments are available for these sheets?

A: A wide range of surface finishes is available, including Hot Rolled, Cold Rolled, 2B, BA, No.1, No.4, Matte, and Mirror. Surface treatments such as bright annealed, pickled, or polished are also offered, allowing customization based on application requirements.Q: When should I consider Incoloy 800H or 800HT instead of standard Incoloy 800?

A: Incoloy 800H and 800HT are preferred when higher strength and enhanced creep resistance are needed at elevated temperatures. Their specific carbon, aluminum, and titanium content make them suitable for prolonged service in the 6001100C temperature range.Q: How does the chemical composition enhance the performance of these alloy sheets?

A: The composition, featuring 30-35% Nickel, 19-23% Chromium, balanced Iron, and additions of Aluminum and Titanium, imparts stability to the microstructure and increases resistance to high-temperature degradation and corrosion.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel Sheets And Plates Category

Inconel 718 Sheets

Material : Other, Inconel 718

Thickness : 0.5 mm to 50 mm

Grade : Inconel 718

Types of Alloy : Other, NickelChromium Superalloy

Strength : High tensile, high yield strength

Inconel 625 Sheets

Material : Other, Inconel 625

Thickness : 0.5 mm to 100 mm

Grade : 625

Types of Alloy : Other, NickelChromium Based Superalloy

Strength : High strength, tough at temperatures up to 980C

Incoloy 825 Sheets

Material : Other, Incoloy 825

Thickness : 0.5 mm to 25 mm

Grade : Incoloy 825 (UNS N08825)

Types of Alloy : Other, NickelIronChromium Alloy

Strength : High mechanical strength

Inconel Sheets

Minimum Order Quantity : 50 Kilograms

Material : Aluminum

Thickness : 15 Millimeter (mm)

Grade : Various Grades Available

Types of Alloy : Aluminum Alloys

Strength : High

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese