Incoloy 825 Sheets

Incoloy 825 Sheets Specification

- Thermal Conductivity

- 11 W/mK at 20C

- Tensile Strength

- 550 MPa min

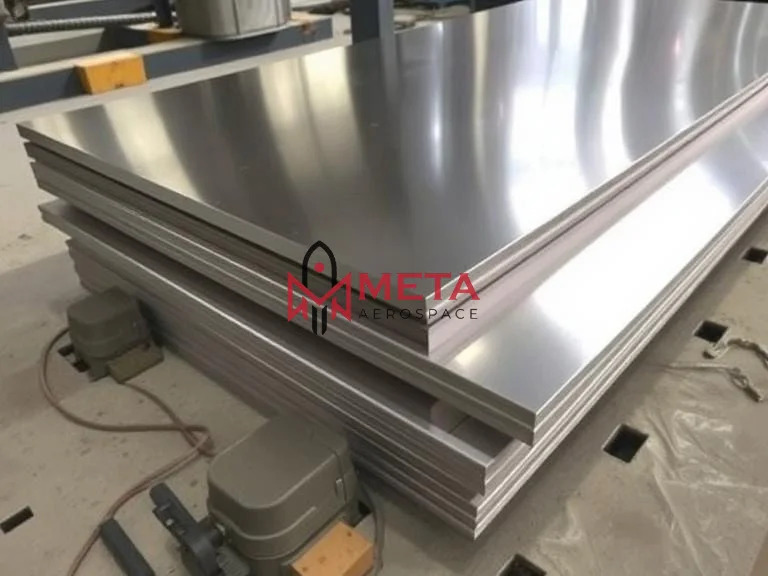

- Thickness

- 0.5 mm to 25 mm

- Product Type

- Sheets

- Types of Alloy

- Nickel-Iron-Chromium Alloy

- Material

- Incoloy 825

- Shape

- Rectangular / Square

- Strength

- High mechanical strength

- Resistance

- Excellent resistance to oxidation, corrosion, and pitting

- Grade

- Incoloy 825 (UNS N08825)

- Melting Point

- 1370 - 1400C

- Density

- 8.14 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Ni 38-46%, Fe 22%, Cr 19.5-23.5%, Mo 2.5-3.5%, Cu 1.5-3%, Ti 0.6-1.2%, Al 0.2%, C 0.05%

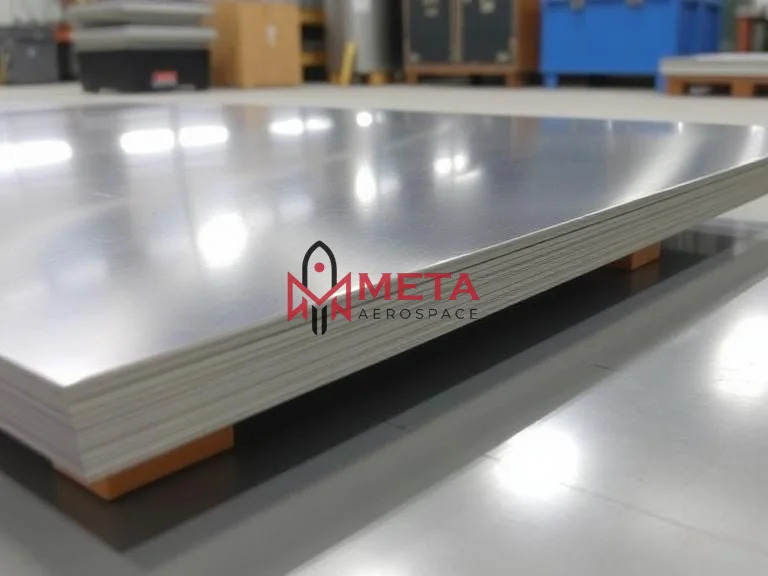

- Color

- Silver / Metallic

- Processing

- Sheared, Plasma Cut, Waterjet Cut, Laser Cut

- Application

- Chemical processing, Oil & Gas, Pollution-control equipment, Pickling operations

- Weldability

- Good

- Specific Heat

- 0.105 Kcal/kg C at 20C

- Surface Finish

- Hot Rolled, Cold Rolled, 2B, BA, No.1, No.4, Mirror finish

- Formability

- Excellent

- Elongation

- 30% min

- Electrical Resistivity

- 1.33 m at 20C

- Standard

- ASTM B424 / ASME SB424

- Machinability

- Good

- Heat Treatment

- Annealed

- Width

- 500 mm to 2500 mm

- Length

- 1000 mm to 6000 mm (custom lengths available)

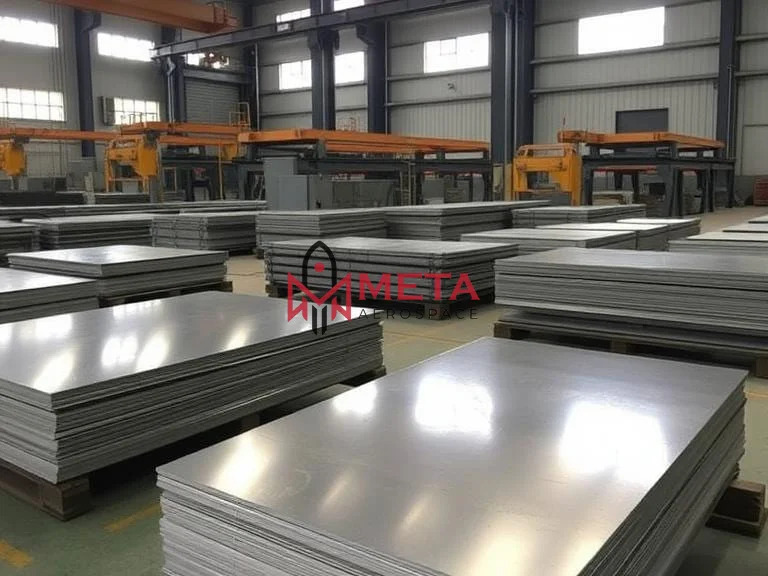

About Incoloy 825 Sheets

What Are Specification Incoloy 825 Sheets?

| Specification | ASTM B168 / ASME SB168 |

|---|---|

| Length | 2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm. |

| Width | 1000mm / 1219mm /1250mm / 1500mm / 2000mm |

| Thickness | Ranging from 0.3mm to 20mm |

| Hardness | As per ASME A & NACE MR 175 |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR) |

Equivalent material Of Incoloy 825 Sheets?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

|---|---|---|---|---|---|---|---|---|

| Incoloy 825 | 2.4858 | N08825 | NCF 825 | NA 16 | 703 | NFE30C20DUM | NiCr21Mo | XH38BT |

Chemical Composition Of Incoloy 825 Sheets?

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Incoloy 825 | 0.05 max | 1 max | 0.5 max | 0.03 max | 1.50 3 | 22.00 min | 38 46 | 19.50 23.50 | 0.02 max | 0.06 1.20 |

Mechanical Properties Of Incoloy 825 Sheets?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.14 g/cm3 | 1400 C (2550 F) | Psi 80,000 , MPa 550 | Psi 32,000 , MPa 220 | 30 % |

Exceptional Corrosion Resistance

Engineered to withstand harsh environments, Incoloy 825 Sheets offer superior resistance to oxidation, intergranular attack, and pitting. Their chemical composition makes them highly suitable for applications in chemical processing and pollution-control operations, where exposure to corrosive agents is frequent.

Versatile Sizing & Finishes

With widths ranging from 500 mm to 2500 mm and lengths up to 6000 mm, plus custom size options, these sheets cater to various project needs. Surface finishes such as Hot Rolled, Cold Rolled, 2B, No.1, BA, No.4, and Mirror are available to meet specific technical or aesthetic requirements.

Reliable Mechanical Properties

Offering a minimum tensile strength of 550 MPa and elongation of at least 30%, Incoloy 825 Sheets excel in both strength and ductility. Their density and hardness further contribute to robust mechanical performance, making them reliable in demanding industries such as oil & gas and pickling operations.

FAQs of Incoloy 825 Sheets:

Q: How are Incoloy 825 Sheets typically processed to meet specific project requirements?

A: Incoloy 825 Sheets can be processed using shearing, plasma cutting, waterjet cutting, and laser cutting. These methods enable precise customization according to required dimensions and shapes, ensuring compatibility with various project needs.Q: What makes Incoloy 825 Sheets suitable for use in chemical processing and pollution-control equipment?

A: Their high resistance to oxidation, corrosion, and pitting, along with excellent mechanical strength and superior chemical stability, make Incoloy 825 Sheets particularly suited for demanding applications like chemical processing plants and pollution-control systems.Q: When should I choose a specific surface finish such as 2B, No.4, or Mirror for Incoloy 825 Sheets?

A: The choice of surface finish depends on the intended application. 2B and No.4 finishes are often selected for industrial uses that demand high corrosion resistance but minimal reflectivity, while Mirror finishes are preferred for applications where aesthetics are crucial alongside performance.Q: Where are Incoloy 825 Sheets commonly exported or supplied from in India?

A: Incoloy 825 Sheets are manufactured and exported by a range of manufacturers, suppliers, and traders based in India, serving both domestic and international markets across industries like oil & gas and chemical processing.Q: What benefits do Incoloy 825 Sheets offer in terms of fabrication and installation?

A: Incoloy 825 Sheets provide excellent formability, good weldability, and machinability, allowing for ease of fabrication, installation, and subsequent modifications during use. These properties streamline both the manufacturing and implementation process in various industries.Q: How does Incoloy 825s chemical composition contribute to its performance?

A: The alloys blend of nickel (38-46%), chromium, iron, molybdenum, copper, titanium, and controlled levels of carbon and aluminum imparts remarkable corrosion resistance and mechanical strength, ensuring reliable performance even in aggressive environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel Sheets And Plates Category

Inconel 718 Sheets

Grade : Inconel 718

Strength : High tensile, high yield strength

Types of Alloy : Other, NickelChromium Superalloy

Thickness : 0.5 mm to 50 mm

Material : Other, Inconel 718

Incoloy 800800H800HT Sheets

Grade : 800, 800H, 800HT

Strength : Excellent high temperature strength

Types of Alloy : Other, NickelIronChromium Alloy

Thickness : 0.5 mm to 50 mm

Material : Other, Incoloy 800/800H/800HT

Inconel 625 Sheets

Grade : 625

Strength : High strength, tough at temperatures up to 980C

Types of Alloy : Other, NickelChromium Based Superalloy

Thickness : 0.5 mm to 100 mm

Material : Other, Inconel 625

Inconel 601 Sheets

Minimum Order Quantity : 50 Kilograms

Grade : Various Grades Available

Strength : High

Types of Alloy : Aluminum Alloys

Thickness : 15 Millimeter (mm)

Material : Aluminum

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese