Inconel 625 Sheets

Inconel 625 Sheets Specification

- Thickness

- 0.5 mm to 100 mm

- Tensile Strength

- 827 MPa (120,000 psi)

- Thermal Conductivity

- 9.8 W/mK at 20C

- Product Type

- Sheets

- Types of Alloy

- Nickel-Chromium Based Superalloy

- Material

- Inconel 625

- Shape

- Flat Sheet

- Strength

- High strength, tough at temperatures up to 980C

- Resistance

- Excellent resistance to corrosion, oxidation, and high temperature

- Grade

- 625

- Melting Point

- 1290C - 1350C

- Density

- 8.44 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Nickel 58%, Chromium 20-23%, Molybdenum 8-10%, Iron 5%, Niobium 3.15-4.15%, Trace elements

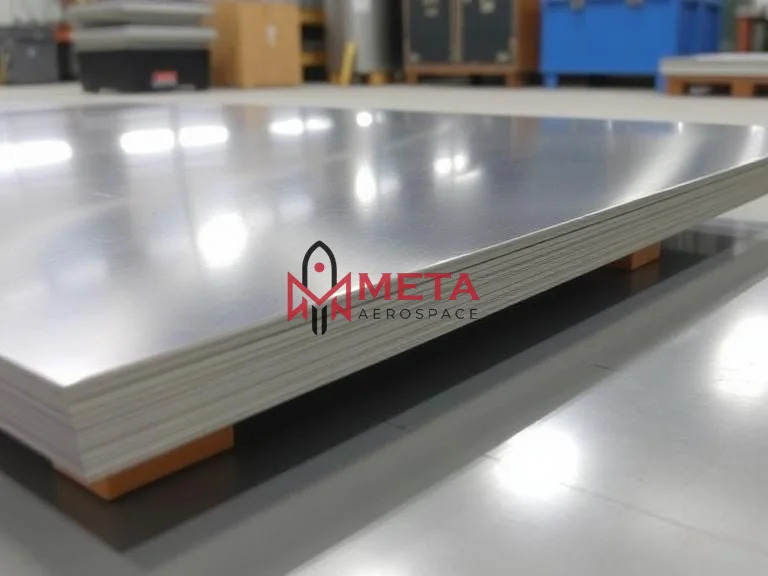

- Color

- Silver-grey

- Yield Strength

- 414 MPa

- Length Range

- Up to 6000 mm

- Elongation

- 30% min

- Processing Capability

- Hot/Cold Rolled

- Packing

- Standard Export Packing

- Application

- Chemical processing, marine, aerospace, heat exchangers, power generation

- Width Range

- 1000 mm to 2500 mm

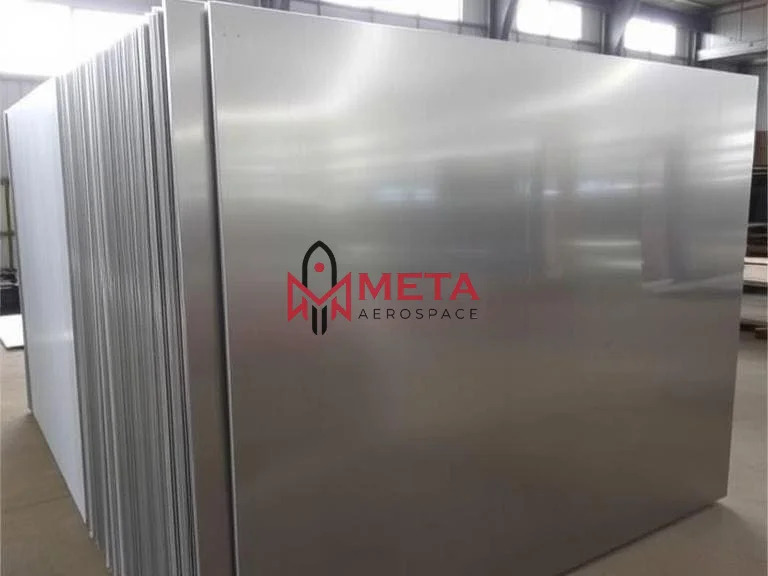

- Surface Finish

- 2B, BA, No. 1, No. 4, Satin

- Standard

- ASTM B443 / ASTM B168

About Inconel 625 Sheets

What Are Specification Inconel 625 Sheets?

| Specification | ASTM B168 / ASME SB168 |

|---|---|

| Length | 2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm. |

| Width | 1000mm / 1219mm /1250mm / 1500mm / 2000mm |

| Thickness | Ranging from 0.3mm to 20mm |

| Hardness | As per ASME A & NACE MR 175 |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR) |

Equivalent material Of Inconel 625 Sheets?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | 75 | NC22DNB4M | NiCr22Mo9Nb |

Chemical Composition Of Inconel 625 Sheets?

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | - | 5.0 max | 58.0 min | 20 - 23 |

Mechanical Properties Of Inconel 625 Sheets?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.4 g/cm3 | 1350 C (2460 F) | Psi 1,35,000 , MPa 930 | Psi 75,000 , MPa 517 | 42.5 % |

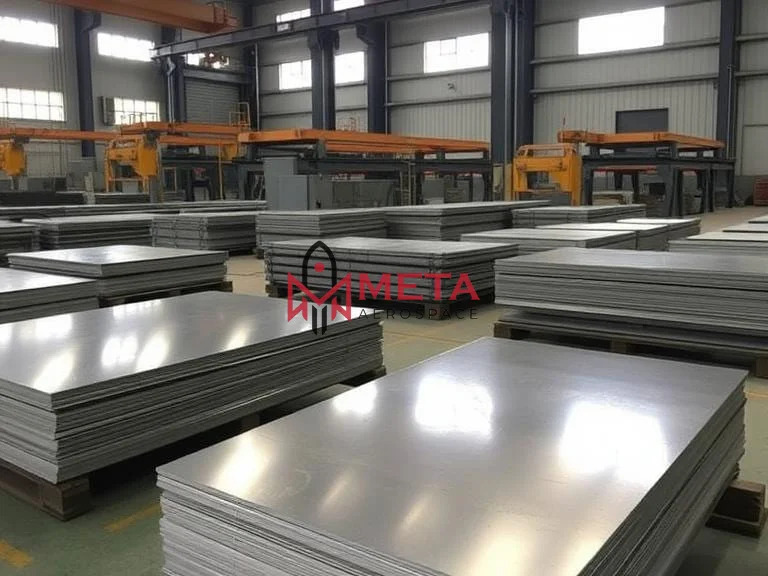

Robust Material for Demanding Applications

Inconel 625 Sheets are engineered for challenging industries such as aerospace, chemical processing, marine environments, and power generation. Their exceptional mechanical properties, including high tensile and yield strengths along with noteworthy elongation, ensure uptime and durability even under high-stress, corrosive, or elevated-temperature conditions. These sheets are available in multiple finishes and thicknesses to suit your project requirements precisely.

Superior Chemical Composition and Resistance

Composed primarily of 58% Nickel, 20-23% Chromium, 8-10% Molybdenum, up to 5% Iron, and 3.15-4.15% Niobium, Inconel 625 Sheets provide excellent corrosion and oxidation resistance. Their structural integrity is maintained even at temperatures as high as 980C. This makes them ideal for heat exchangers and components in harsh chemical and marine settings.

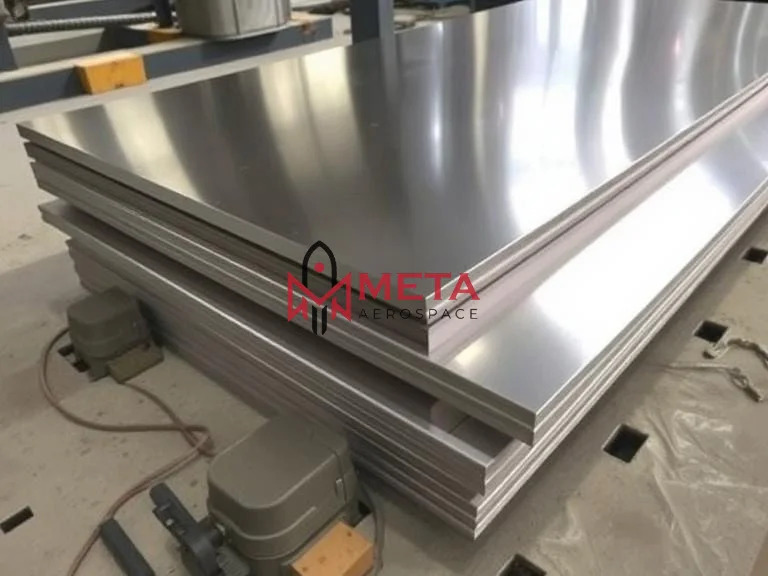

Flexible Processing and Precision Standards

Produced according to ASTM B443 and ASTM B168 standards, Inconel 625 Sheets can be hot or cold rolled to specified thicknesses, from 0.5 mm to 100 mm. Their versatility extends to diverse surface finishes (2B, BA, No. 1, No. 4, Satin), with each sheet undergoing strict quality control and standard export packing to ensure safe global delivery.

FAQs of Inconel 625 Sheets:

Q: How are Inconel 625 Sheets processed to achieve different finishes and dimensions?

A: Inconel 625 Sheets are manufactured using either hot or cold rolling techniques, which allows precise control over thickness (from 0.5 mm to 100 mm) and surface finishes such as 2B, BA, No. 1, No. 4, and Satin. This advanced processing ensures strong, flat sheets with the required mechanical properties for demanding applications.Q: What makes Inconel 625 Sheets highly suitable for chemical processing and marine environments?

A: Their unique chemical compositionrich in nickel, chromium, molybdenum, and niobiumprovides outstanding resistance to corrosion and oxidation. This makes them exceptionally well-suited for chemical processing plants and marine settings where exposure to aggressive chemicals and saltwater commonly occurs.Q: When should I choose Inconel 625 Sheets over other alloy sheets?

A: You should select Inconel 625 Sheets when your application requires superior strength, toughness at temperatures up to 980C, and resistance to corrosion or oxidation. These sheets are ideal for heat exchangers, power generation parts, and aerospace components exposed to aggressive thermal or chemical environments.Q: Where are Inconel 625 Sheets commonly used in industry?

A: Inconel 625 Sheets find widespread use in the chemical processing industry, marine constructions, heat exchanger fabrication, aerospace parts, and power generation components. Their robustness and resistance make them a preferred choice in environments subject to high stress, temperature, and corrosive agents.Q: What is the thermal conductivity and density of Inconel 625 Sheets?

A: The sheets have a thermal conductivity of 9.8 W/mK at 20C and a density of 8.44 g/cm3, making them suitable for thermal management in high-temperature environments as well as providing weight benefits for specialized industrial needs.Q: How does Inconel 625 benefit heat exchanger and power generation applications?

A: Thanks to its high yield and tensile strengths and excellent performance at elevated temperatures, Inconel 625 guarantees minimal deformation and long service life in heat exchangers and power generation systems, where mechanical and thermal stresses are constantly encountered.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel Sheets And Plates Category

Incoloy 800800H800HT Sheets

Material : Other, Incoloy 800/800H/800HT

Thickness : 0.5 mm to 50 mm

Grade : 800, 800H, 800HT

Strength : Excellent high temperature strength

Types of Alloy : Other, NickelIronChromium Alloy

Inconel 718 Sheets

Material : Other, Inconel 718

Thickness : 0.5 mm to 50 mm

Grade : Inconel 718

Strength : High tensile, high yield strength

Types of Alloy : Other, NickelChromium Superalloy

Incoloy 825 Sheets

Material : Other, Incoloy 825

Thickness : 0.5 mm to 25 mm

Grade : Incoloy 825 (UNS N08825)

Strength : High mechanical strength

Types of Alloy : Other, NickelIronChromium Alloy

Inconel 601 Sheets

Minimum Order Quantity : 50 Kilograms

Material : Aluminum

Thickness : 15 Millimeter (mm)

Grade : Various Grades Available

Strength : High

Types of Alloy : Aluminum Alloys

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese