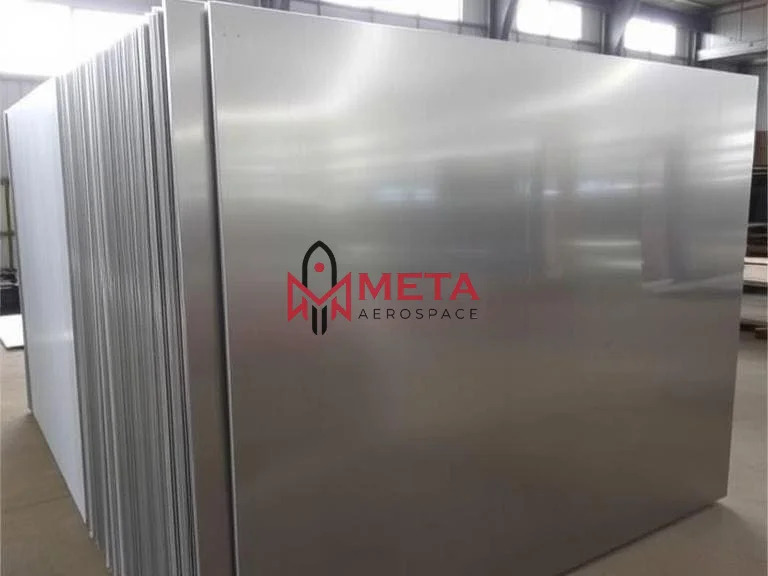

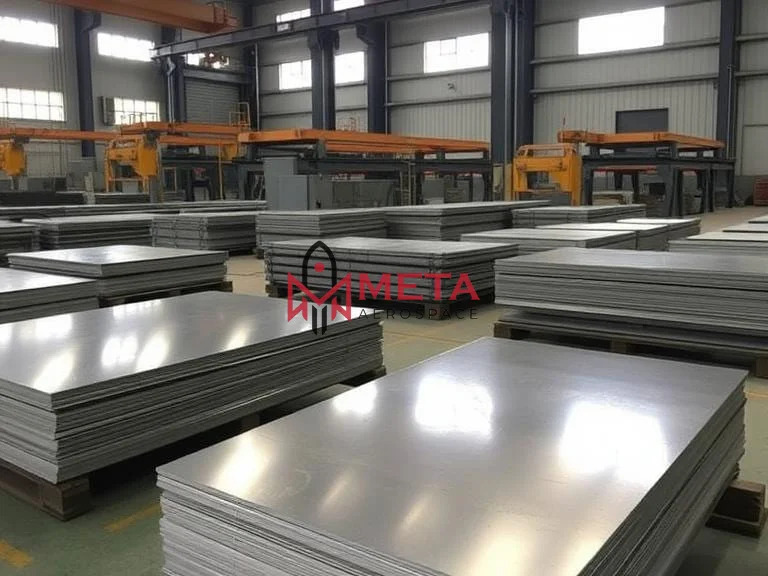

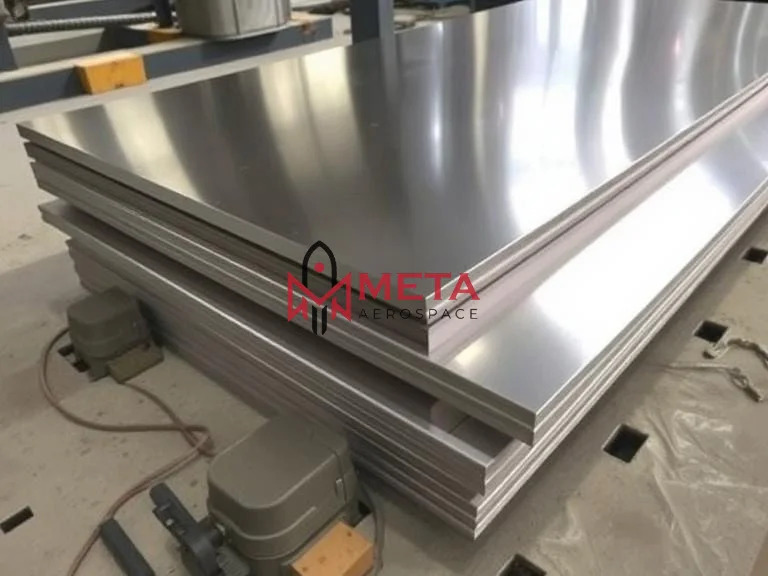

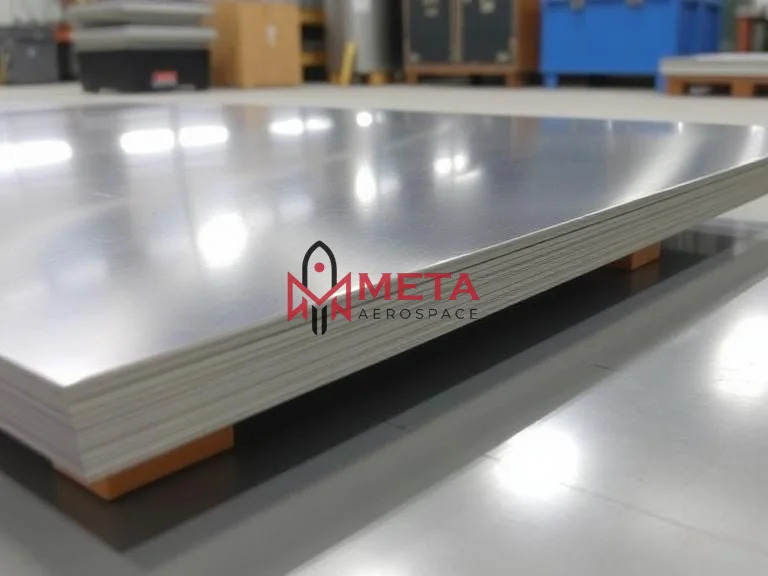

Inconel 718 Sheets

Inconel 718 Sheets Specification

- Thickness

- 0.5 mm to 50 mm

- Thermal Conductivity

- 11.4 W/mK at 21C

- Tensile Strength

- 1240 MPa min

- Product Type

- Sheets

- Types of Alloy

- Nickel-Chromium Superalloy

- Material

- Inconel 718

- Shape

- Rectangular Sheets

- Strength

- High tensile, high yield strength

- Resistance

- Excellent corrosion and oxidation resistance

- Grade

- Inconel 718

- Melting Point

- 12601336C

- Density

- 8.19 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Ni 50-55%, Cr 17-21%, Fe bal., Nb+Ta 4.75-5.5%, Mo 2.8-3.3%, Ti 0.65-1.15%, Al 0.2-0.8%

- Color

- Silver Grey

- Length

- up to 6000 mm or as required

- Finish

- Hot Rolled, Cold Rolled, Polished

- Width

- up to 2000 mm

- Weldability

- Good

- Machinability

- Fair, requires rigid tools

- Standard

- ASTM B670, AMS 5596

- Service Temperature

- Up to 700C

- Applications

- Aerospace, Gas Turbines, Nuclear Reactors, Oil & Gas

- Surface Treatment

- Pickled, Annealed

- Elongation

- 12% min

About Inconel 718 Sheets

What Are Specification Inconel 718 Sheets?

| Specification | ASTM B168 / ASME SB168 |

|---|---|

| Length | 2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm. |

| Width | 1000mm / 1219mm /1250mm / 1500mm / 2000mm |

| Thickness | Ranging from 0.3mm to 20mm |

| Hardness | As per ASME A & NACE MR 175 |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR) |

Equivalent material Of Inconel 718 Sheets?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Inconel 718 | 2.4668 | N07718 |

Chemical Composition Of Inconel 718 Sheets?

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | - | 50 - 55 | 17 - 21 |

Mechanical Properties Of Inconel 718 Sheets?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.4 g/cm3 | 1350 C (2460 F) | Psi 1,35,000 , MPa 930 | Psi 75,000 , MPa 517 | 42.5 % |

Superior Material Composition and Strength

Inconel 718 Sheets are meticulously engineered with a blend of nickel, chromium, molybdenum, and other elements, enhancing both mechanical strength and corrosion resistance. These sheets maintain their integrity at high service temperatures (up to 700C) and feature a tensile strength of at least 1240 MPa, making them a reliable choice for challenging industrial applications.

Versatile Applications in Critical Industries

Owing to their remarkable resistance to oxidation and corrosion, Inconel 718 Sheets are a preferred material in sectors such as aerospace, gas turbines, nuclear reactors, and oil & gas. Their robust properties, including fair machinability and good weldability, ensure reliable performance under demanding operational conditions.

Flexible Manufacturing and Customization Options

These sheets are available in several finisheshot rolled, cold rolled, and polishedwith customizable dimensions to suit specific project needs. Widely supplied by manufacturers and exporters across India, Inconel 718 Sheets are always processed with precision surface treatments like pickling and annealing for optimum durability.

FAQs of Inconel 718 Sheets:

Q: How are Inconel 718 Sheets typically processed before delivery?

A: Inconel 718 Sheets undergo treatments such as pickling and annealing. They are available in various finishes including hot rolled, cold rolled, and polished, ensuring optimal mechanical and surface properties tailored to application requirements.Q: What industries most commonly use Inconel 718 Sheets, and why?

A: Industries such as aerospace, gas turbines, nuclear reactors, and oil & gas often use Inconel 718 Sheets due to their high tensile strength, excellent corrosion and oxidation resistance, and ability to withstand elevated temperatures up to 700C.Q: When is it beneficial to choose Inconel 718 Sheets over other alloys?

A: Selecting Inconel 718 Sheets is ideal when applications demand high mechanical strength, resistance to corrosion, and performance at high temperatures. Their superior properties make them highly suitable for environments where reliability and durability are critical.Q: Where are Inconel 718 Sheets manufactured and supplied from?

A: Inconel 718 Sheets are manufactured, exported, and supplied by reputable producers and traders based in India, serving both domestic and international markets with custom dimensions and finishes as required.Q: What are the key advantages of using Inconel 718 Sheets in industrial applications?

A: Key benefits include excellent mechanical strength, high elongation (12% min), superior oxidation and corrosion resistance, and the ability to retain performance under extreme conditions. These attributes translate to longer service life and reduced maintenance costs.Q: How does the machinability and weldability of Inconel 718 Sheets affect their usage?

A: Inconel 718 Sheets offer fair machinabilityrequiring rigid tools and proper techniqueswhile also providing good weldability. This balance allows manufacturers to fabricate complex components for high-stress applications with confidence in the materials integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel Sheets And Plates Category

Inconel 625 Sheets

Material : Other, Inconel 625

Thickness : 0.5 mm to 100 mm

Grade : 625

Strength : High strength, tough at temperatures up to 980C

Types of Alloy : Other, NickelChromium Based Superalloy

Incoloy 800800H800HT Sheets

Material : Other, Incoloy 800/800H/800HT

Thickness : 0.5 mm to 50 mm

Grade : 800, 800H, 800HT

Strength : Excellent high temperature strength

Types of Alloy : Other, NickelIronChromium Alloy

Incoloy 825 Sheets

Material : Other, Incoloy 825

Thickness : 0.5 mm to 25 mm

Grade : Incoloy 825 (UNS N08825)

Strength : High mechanical strength

Types of Alloy : Other, NickelIronChromium Alloy

Inconel Sheets

Minimum Order Quantity : 50 Kilograms

Material : Aluminum

Thickness : 15 Millimeter (mm)

Grade : Various Grades Available

Strength : High

Types of Alloy : Aluminum Alloys

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese