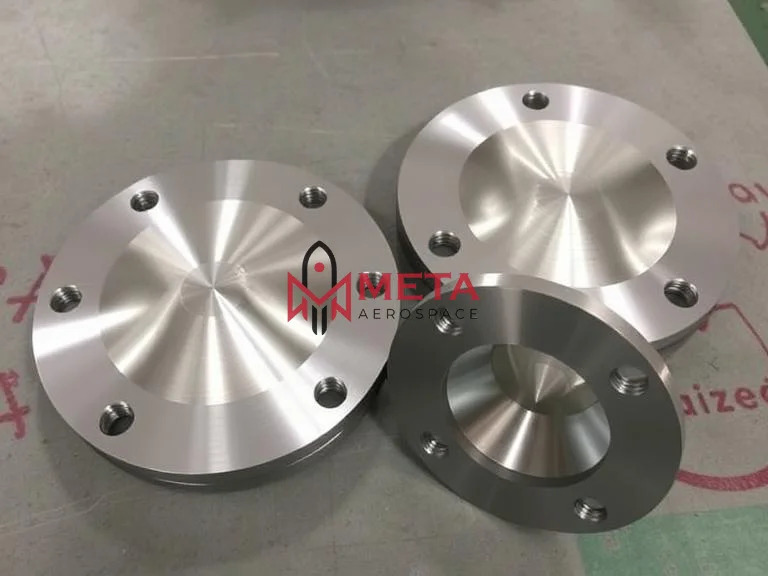

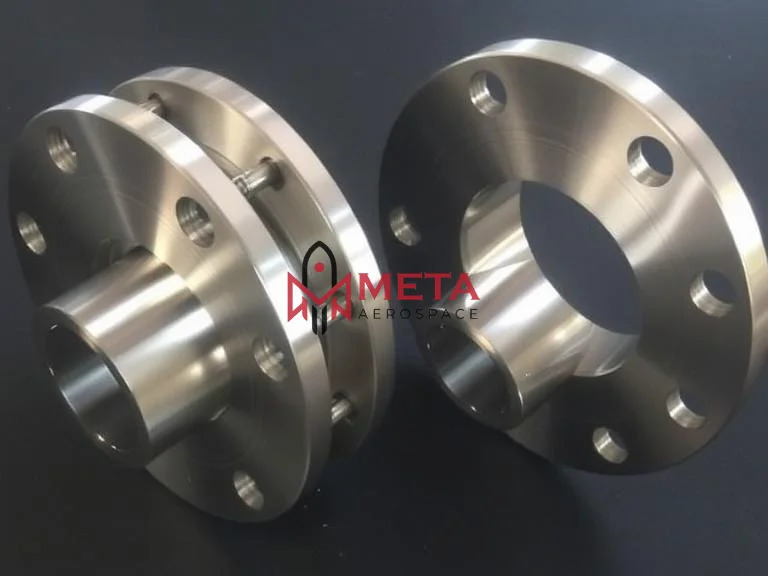

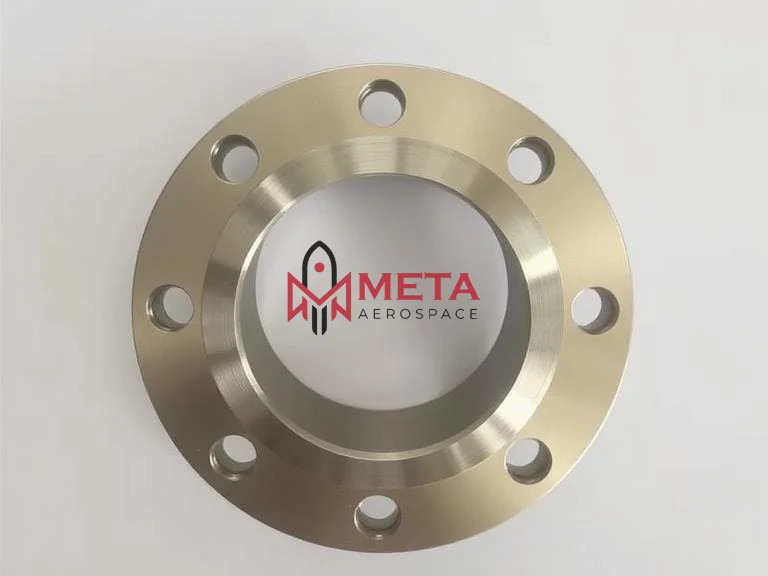

Stainless Steel 304304L Flanges

Stainless Steel 304304L Flanges Specification

- Application

- Petrochemical, Power Generation, Oil and Gas, Water Treatment, Food Processing

- Feature

- Corrosion resistance, high strength, durability

- Dimension (L*W*H)

- As per standard specifications and customer requirement

- Grade

- 304/304L

- Purity

- Greater than 99%

- Product Type

- Flange

- Material

- Stainless Steel 304/304L

- Standard

- Shape

- Round

- Surface

- Polished / Mirror / Matt finish

- Connection

- Welded, Threaded, Socket Weld, Slip-on, Blind, Lap Joint, Flange

- Technics

- Forged

- Pressure

- Class 150#, 300#, 600#, 900#, 1500#, 2500#

- Size

- 1/2 to 48 (DN15 to DN1200)

- Color

- Silver

- Hardness

- 160 - 210 HB

- End Type

- Weld Neck, Slip-On, Socket Weld, Blind, Threaded, Lap Joint, Spectacle Blind

- Finish Type

- Smooth & Burr-free

- Marking

- Size, Pressure Rating, Material Grade and Heat Number

- Flange Face Type

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Density

- 7.93 g/cm

- Packaging

- Wooden Cases, Pallets, Bubble Wrap

- Temperature Range

- -40C to 800C

- Sealing Method

- Gasket

- Tolerance

- As per ASME/ANSI B16.5 / DIN / JIS / BS standards

About Stainless Steel 304304L Flanges

What Are Specification Stainless Steel 304/304L Flanges?

| Specifications List | ASTM A182 / ASME SA182 |

|---|---|

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Size Chart | 1/2 (15 NB) to 48 (1200NB) |

| ASTM Standards | ANSI/ASME B16.5, B16.48, BS4504, B 16.47 Series A & B, BS 10, EN-1092, DIN, etc. |

| Standard s | ANSI, ASME, BS, DIN, EN etc. |

Equivalent material Of Stainless Steel 304/304L Flanges?

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

|---|---|---|---|---|---|---|---|

| SS 304 | S30400 | 1.4301 | Z7CN1809 | X5CrNi18-10 | SUS 304 | 304S31 | 081810 |

| SS 304L | S30403 | 1.4306/1.4307 | Z3CN1810 | X2CrNi18-9 / X2CrNi19-11 | SUS 304L | 304S11 | 031811 |

Chemical Composition Of Stainless Steel 304/304L Flanges?

| Grade | C | Mn | Si | P | S | Cr | Ni | N |

|---|---|---|---|---|---|---|---|---|

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 20 | 8 11 | - |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 20 | 8 13 | - |

Mechanical Properties Of Stainless Steel 304/304L Flanges?

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| SS 304/304L | 8.0 g/cm3 | 1400 C (2550 F) | Psi 75000, MPa 515 | Psi 30000, MPa 205 | 40 % |

Exceptional Strength and Durability

Engineered from Stainless Steel 304/304L, these flanges offer a density of 7.93 g/cm and a hardness range between 160 and 210 HB, enabling them to perform in demanding environments like oil and gas, petrochemical, power generation, and water treatment. Their reliable composition ensures longevity, minimizing maintenance needs and downtime.

Versatile Application and Customization

Available in sizes ranging from 1/2 inch to 48 inches (DN15 to DN1200), with multiple face and connection types, these flanges can be tailored according to specific dimension, pressure, and finish requirements. Their adaptability allows seamless integration into new installations or existing systems, enhancing operational flexibility.

FAQs of Stainless Steel 304304L Flanges:

Q: How are Stainless Steel 304/304L flanges typically used in industrial applications?

A: These flanges are widely deployed in connecting pipes, valves, pumps, and other equipment across industries such as petrochemical, power generation, oil and gas, water treatment, and food processing. Their corrosion resistance and strength make them suitable for harsh and high-pressure environments.Q: What benefits do 304/304L stainless steel flanges provide over other material grades?

A: 304/304L stainless steel flanges deliver superior corrosion resistance, excellent mechanical properties, high purity, and extended durability. These characteristics make them cost-effective in environments where chemical exposure and extreme temperatures are factors.Q: When should I choose Raised Face, Flat Face, or Ring Type Joint flange face types?

A: Selecting the appropriate flange face depends on the application requirements: Raised Face (RF) for high-pressure sealing, Flat Face (FF) for systems with flat-faced mating parts, and Ring Type Joint (RTJ) for environments demanding enhanced leak protection under high temperature and pressure.Q: Where are these flanges manufactured and how are they packaged for shipping?

A: Manufactured and supplied from India, these flanges are exported globally. To prevent damage during transit, each flange is marked with size, pressure, material grade, and heat number and securely packaged in wooden cases, pallets, or bubble wrap as required.Q: What process is used to manufacture Stainless Steel 304/304L flanges?

A: These flanges are primarily produced by forging, according to international standards such as ASME/ANSI B16.5. This process ensures uniformity, mechanical strength, and a smooth finish, tailored to specific customer or industry specifications.Q: How should I specify the correct flange for my project?

A: It is crucial to consider parameters such as flange face type, end connection, pressure class, size, material grade, and required finish. Sharing detailed application requirements with the supplier ensures the most suitable flange is provided for your system.Q: What sealing method is recommended for Stainless Steel 304/304L flanges?

A: Sealing is typically achieved using gaskets compatible with the flange face type, ensuring a reliable, leak-proof connection suitable for the operating pressure and temperature range.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Flanges Category

Stainless Steel 310310S Flanges

Size : 1/2 NB to 48 NB

Purity : 99%

Technics : Other, Forged

Surface : Other, Bright, Polished

Material : Stainless Steel

Grade : SS 310 / SS 310S

Stainless Steel 317317L Flanges

Size : 1/2 to 24 (DN15DN600)

Purity : 99%

Technics : Other, Forged

Surface : Other, Polished

Material : Stainless Steel

Grade : 317 / 317L

Stainless Steel 316316L316H Flanges

Size : 1/2 NB to 48 NB (DN15DN1200)

Purity : High Purity Stainless Steel

Technics : Other, Forged / Cast

Surface : Other, Bright, Polished, Antirust oil

Material : Stainless Steel 316, 316L, 316H

Grade : 316 / 316L / 316H

Stainless Steel 316Ti Flanges

Size : 1/2 to 24 (DN15 to DN600)

Purity : Premium quality with low carbon content

Technics : Other, Forged / Casting

Surface : Other, Polished / Smooth

Material : Stainless Steel 316Ti

Grade : 316Ti

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese