Stainless Steel 317317L Flanges

Stainless Steel 317317L Flanges Specification

- Feature

- Corrosion Resistance, High Strength, Durable

- Application

- Petrochemical, Chemical Industry, Oil & Gas, Power Plants

- Purity

- 99%

- Dimension (L*W*H)

- As per ASME/ANSI B16.5

- Grade

- 317 / 317L

- Product Type

- Pipe Flange

- Material

- Stainless Steel

- Standard

- ASTM A182 / ASME SA 182

- Shape

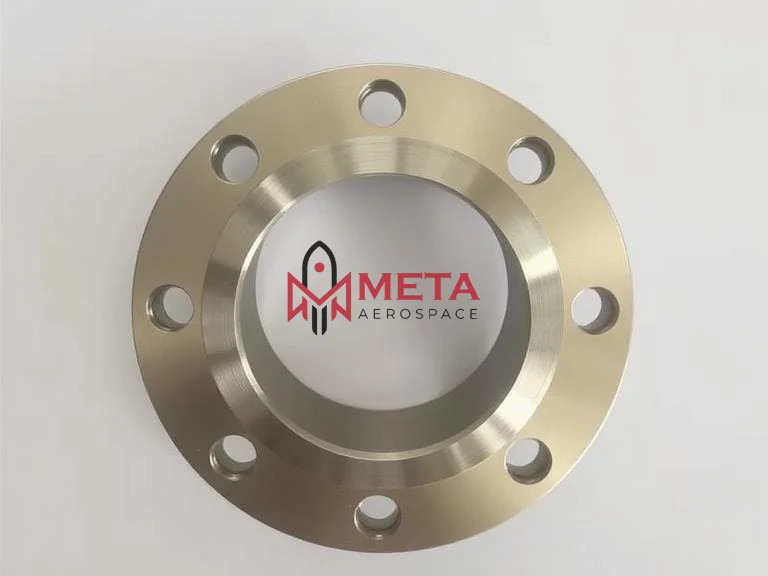

- Round

- Surface

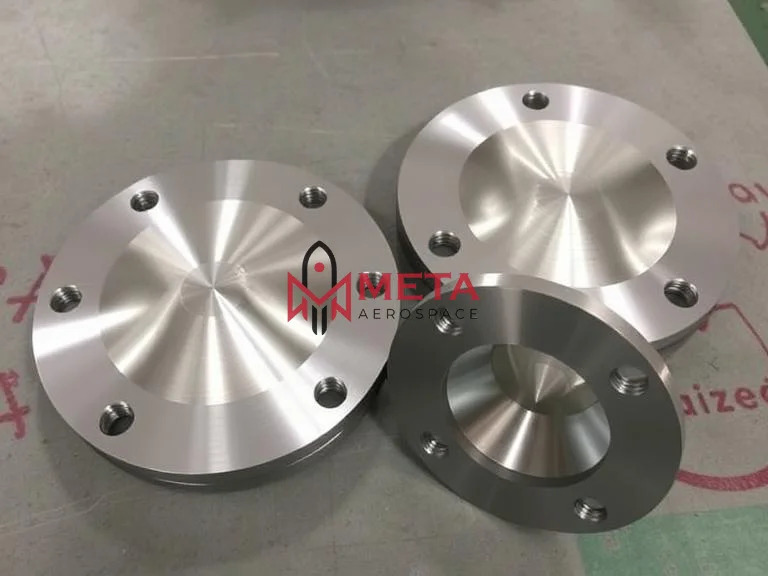

- Polished

- Connection

- Welded / Bolted

- Technics

- Forged

- Pressure

- 150# to 2500#

- Size

- 1/2 to 24 (DN15-DN600)

- Color

- Silver

- Face Type

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Hardness

- Brinell 217

- Packaging

- Wooden Boxes

- Tolerance

- As per ASME/ANSI standard

- Temperature Range

- Up to 870C

- End

- Flanged

- Schedule

- SCH 10, SCH 40, SCH 80, SCH 160

- UNS Number

- S31700 / S31703

- Density

- 7.90 g/cm

- Manufacturing Process

- Hot Forged / Machined

- Melting Point

- 1398C 1454C

- Type

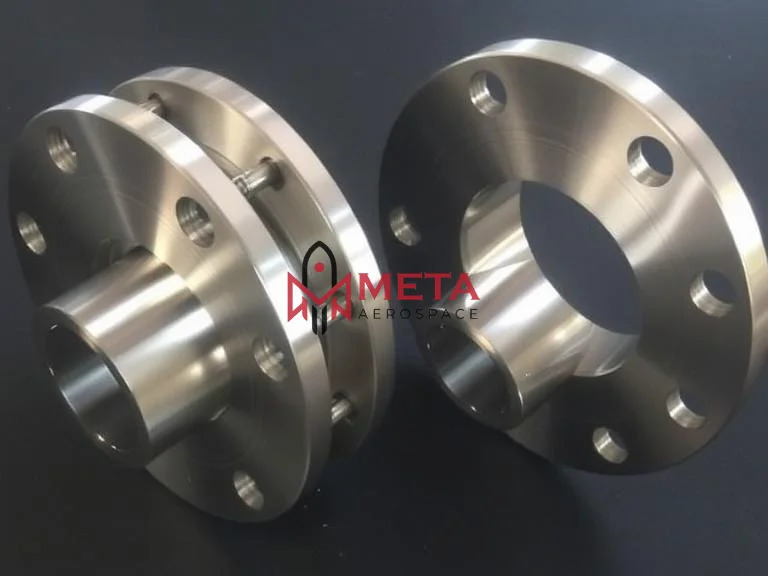

- Slip On, Blind, Weld Neck, Socket Weld, Threaded, Lap Joint

About Stainless Steel 317317L Flanges

What Are Specification Stainless Steel 317/317L Flanges?

| Specifications List | ASTM A182 / ASME SA182 |

|---|---|

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Size Chart | 1/2 (15 NB) to 48 (1200NB) |

| ASTM Standards | ANSI/ASME B16.5, B16.48, BS4504, B 16.47 Series A & B, BS 10, EN-1092, DIN, etc. |

| Standard s | ANSI, ASME, BS, DIN, EN etc. |

Equivalent material Of Stainless Steel 317/317L Flanges?

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| SS 317 | S31700 | 1.4449 | SUS 317 | - |

| SS 317L | S31703 | 1.4438 | SUS 317L | X2CrNiMo18-15-4 |

Chemical Composition Of Stainless Steel 317/317L Flanges?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

Mechanical Properties Of Stainless Steel 317/317L Flanges?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 C (2555 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

Wide Range of Types and Sizes

Our Stainless Steel 317/317L flanges are available in Slip On, Blind, Weld Neck, Socket Weld, Threaded, and Lap Joint variants. Ranging from 1/2 to 24 inches (DN15DN600), these round flanges are manufactured as per ASME/ANSI B16.5 dimensional standards, ensuring precise fit for various industrial applications.

Superior Corrosion Resistance

Engineered from high-purity 99% stainless steel, Grade 317/317L, these flanges are designed for maximum corrosion resistance. This makes them ideal for harsh environments found in petrochemical plants, chemical industries, oil & gas operations, and power generation facilities.

High Temperature and Pressure Endurance

With a melting point between 1398C and 1454C and a temperature range up to 870C, these flanges reliably operate under extreme thermal conditions. They also support pressure ratings from 150# to 2500#, accommodating a variety of piping requirements efficiently.

FAQs of Stainless Steel 317317L Flanges:

Q: How are Stainless Steel 317/317L Flanges manufactured?

A: These flanges are produced through a hot forged and machined process, followed by polishing to ensure a smooth, corrosion-resistant surface. Each piece is crafted to meet ASTM A182 / ASME SA 182 standards, guaranteeing quality and precision.Q: What industries commonly use 317/317L flanges?

A: Stainless Steel 317/317L flanges are widely deployed in sectors like petrochemical, chemical, oil & gas, and power plants due to their impressive corrosion resistance and ability to handle high temperatures and pressures.Q: When should I choose a Raised Face (RF), Flat Face (FF), or Ring Type Joint (RTJ) flange?

A: Choose RF for general-purpose, moderate-pressure applications; FF when connecting to equipment with flat-faced flanges; and RTJ for high-pressure systems requiring a robust seal. Selection depends on your operating conditions and compatibility needs.Q: Where are these flanges typically installed?

A: These flanges are primarily installed within pipelines and equipment connections in refineries, chemical plants, oil & gas extraction sites, and power generation facilities, serving as essential connectors for safe, leak-proof operations.Q: What are the main benefits of using 317/317L flanges in industrial applications?

A: Key benefits include excellent resistance to corrosion and chemicals, high mechanical strength, durability in extreme temperatures up to 870C, and compliance with international standards, ensuring long service life and low maintenance costs.Q: How does the schedule (SCH 10, SCH 40, SCH 80, SCH 160) affect flange selection?

A: The schedule denotes wall thicknesshigher schedules support greater pressure and are chosen based on system demands. Select the schedule that matches your pipelines pressure, flow requirements, and safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Flanges Category

Stainless Steel 310310S Flanges

Standard : Other, ANSI, ASME, DIN, JIS, BS, EN

Technics : Other, Forged

Purity : 99%

Grade : SS 310 / SS 310S

Size : 1/2 NB to 48 NB

Surface : Other, Bright, Polished

Stainless Steel 304304L Flanges

Standard : Other, ASME/ANSI B16.5, DIN, JIS, BS and other international standards

Technics : Other, Forged

Purity : Greater than 99%

Grade : 304/304L

Size : 1/2 to 48 (DN15 to DN1200)

Surface : Other, Polished / Mirror / Matt finish

Stainless Steel 316Ti Flanges

Standard : Other, ASTM A182 / ASME SA182

Technics : Other, Forged / Casting

Purity : Premium quality with low carbon content

Grade : 316Ti

Size : 1/2 to 24 (DN15 to DN600)

Surface : Other, Polished / Smooth

Stainless Steel 316316L316H Flanges

Standard : Other, ASTM A182 / ASME SA182, ANSI, DIN, JIS, BS, EN, GOST

Technics : Other, Forged / Cast

Purity : High Purity Stainless Steel

Grade : 316 / 316L / 316H

Size : 1/2 NB to 48 NB (DN15DN1200)

Surface : Other, Bright, Polished, Antirust oil

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese