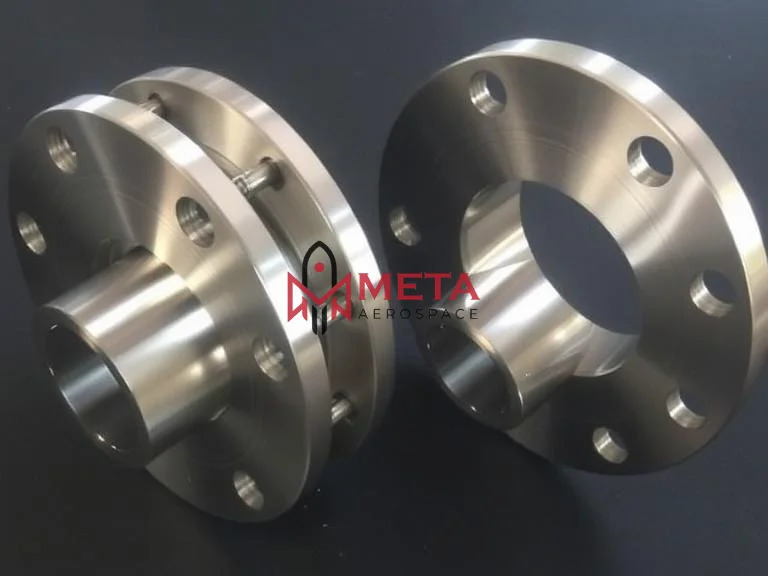

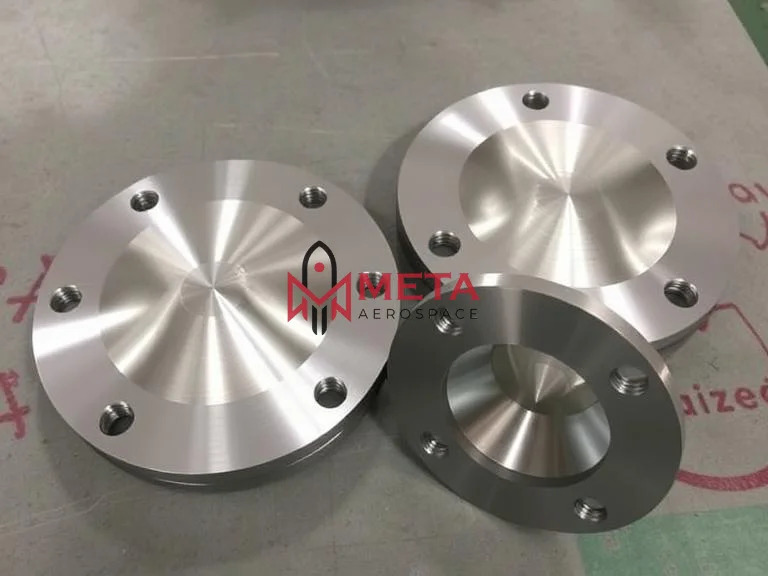

Stainless Steel 310310S Flanges

Stainless Steel 310310S Flanges Specification

- Application

- Petrochemical, Oil & Gas, Power Plants, Chemical Processing, Heat Exchangers, Furnace Parts

- Feature

- Corrosion resistant, Heat resistant, Durable

- Dimension (L*W*H)

- As per standards

- Purity

- 99%

- Grade

- SS 310 / SS 310S

- Product Type

- Flanges

- Material

- Stainless Steel

- Standard

- ANSI, ASME, DIN, JIS, BS, EN

- Shape

- Round

- Surface

- Bright, Polished

- Connection

- Welded, Screwed, Slip On, Socket Weld, Blind, Lap Joint, Threaded, Orifice

- Technics

- Forged

- Pressure

- Class 150, Class 300, Class 600, Class 900, Class 1500, Class 2500

- Size

- 1/2 NB to 48 NB

- Color

- Silver

- Tensile Strength

- 515 MPa (minimum)

- Yield Strength

- 205 MPa (minimum)

- Hardness

- 95 HRB

- Density

- 7.9 g/cm

- Packaging

- Wooden Cases/Pallets

- End Type

- Plain, Beveled, Raised Face

- Maximum Operating Temperature

- Up to 1150C

- Spectral Analysis

- Available

- Finish Type

- Mirror/Matte/Custom

- Rust Resistance

- High

About Stainless Steel 310310S Flanges

What Are Specification Stainless Steel 310/310S Flanges?

| Specifications List | ASTM A182 / ASME SA182 |

|---|---|

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Size Chart | 1/2 (15 NB) to 48 (1200NB) |

| ASTM Standards | ANSI/ASME B16.5, B16.48, BS4504, B 16.47 Series A & B, BS 10, EN-1092, DIN, etc. |

| Standard s | ANSI, ASME, BS, DIN, EN etc. |

Equivalent material Of Stainless Steel 310/310S Flanges?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | X15CrNi25-20 | |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | X8CrNi25-21 |

Chemical Composition Of Stainless Steel 310/310S Flanges?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2 max | 0.015 max | 0.020 max | 0.015 max | 24.00 26.00 | 0.10 max | 19.00 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2 max | 1.00 max | 0.045 max | 0.030 max | 24.00 26.00 | 0.75 max | 19.00 21.00 | 53.095 min |

Mechanical Properties Of Stainless Steel 310/310S Flanges?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 C (2555 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

Exceptional Heat and Corrosion Resistance

Stainless Steel 310/310S flanges are renowned for their superior heat resistance, withstanding operating temperatures up to 1150C. Their high chromium and nickel content ensures long-term performance in corrosive environments, making them suitable for sectors like chemical processing and power generation. These properties significantly reduce maintenance and enhance safety in extreme conditions.

Versatile Applications and Customization

These flanges offer outstanding versatility in terms of end types (plain, beveled, raised face) and finishes (mirror, matte, or custom), catering to diverse industrial needs. Sourced in a broad range of sizes and compatible with various connection techniqueswelded, screwed, orificed, and morethey can adapt to a wide array of systems in petrochemical, oil & gas, and other heavy-duty applications.

FAQs of Stainless Steel 310310S Flanges:

Q: How are Stainless Steel 310/310S flanges typically used in industry?

A: These flanges are primarily utilized in high-temperature and corrosive environments such as petrochemical plants, oil & gas refineries, power plants, chemical processing facilities, heat exchangers, and furnace parts. Their robust construction ensures secure connections in piping systems, enabling safe processing under harsh conditions.Q: What benefits do SS 310/310S flanges provide compared to other stainless steels?

A: SS 310/310S flanges offer superior heat and corrosion resistance, supporting temperatures up to 1150C and resisting oxidation and scaling. Their high strength and durability increase the longevity and safety of systems, making them preferable for applications requiring both toughness and thermal resilience.Q: When should I opt for a mirror, matte, or custom finish on these flanges?

A: The finish type is determined by operational needs and aesthetic preferences. Mirror finishes provide enhanced corrosion resistance and an attractive appearance, ideal for visible or hygienic applications. Matte and custom finishes may be selected for environments requiring less reflectivity or specific technical criteria.Q: Where are Stainless Steel 310/310S flanges manufactured and exported from?

A: These flanges are widely manufactured, exported, and supplied by trusted companies in India, adhering to international standards such as ANSI, ASME, DIN, JIS, BS, and EN. They are shipped globally in robust packaging like wooden cases and pallets to ensure safe delivery.Q: What processes are involved in producing SS 310/310S flanges?

A: The flanges are typically forged, shaped, and machined according to precise standards. Quality control includes spectral analysis to verify material composition, dimensional checks, and surface finishing to achieve the required mirror, matte, or custom finishes. This manufacturing process ensures consistency, purity, and performance.Q: How does the connection typesuch as welded or threadedaffect flange selection?

A: The connection type depends on the installation requirements. Welded flanges offer leak-proof integration and strength, while threaded or screwed options facilitate easy assembly and maintenance. Slip-on, socket weld, blind, lap joint, and orifice types accommodate different piping layouts and operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Flanges Category

Stainless Steel 316316L316H Flanges

Size : 1/2 NB to 48 NB (DN15DN1200)

Material : Stainless Steel 316, 316L, 316H

Grade : 316 / 316L / 316H

Purity : High Purity Stainless Steel

Technics : Other, Forged / Cast

Surface : Other, Bright, Polished, Antirust oil

Stainless Steel 304304L Flanges

Size : 1/2 to 48 (DN15 to DN1200)

Material : Stainless Steel 304/304L

Grade : 304/304L

Purity : Greater than 99%

Technics : Other, Forged

Surface : Other, Polished / Mirror / Matt finish

Stainless Steel 317317L Flanges

Size : 1/2 to 24 (DN15DN600)

Material : Stainless Steel

Grade : 317 / 317L

Purity : 99%

Technics : Other, Forged

Surface : Other, Polished

Stainless Steel 321321H Flanges

Size : 1/2 to 60 (DN15DN1500)

Material : Stainless Steel 321/321H

Grade : 321 / 321H

Purity : >99%

Technics : Other, Forged

Surface : Other, Polished / Machined

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese