Stainless Steel 321321H Flanges

Stainless Steel 321321H Flanges Specification

- Application

- Oil & Gas, Petrochemical, Power Plant, Chemical Industry, Shipbuilding, Paper & Pulp

- Feature

- Corrosion Resistance, High Temperature Resistance, Durability, Precise Dimensions

- Dimension (L*W*H)

- Custom as per Order

- Grade

- 321 / 321H

- Purity

- >99%

- Product Type

- Flange

- Material

- Stainless Steel 321/321H

- Standard

- ASTM A182, ANSI B16.5, DIN, JIS, BS, GB, IS

- Shape

- Round

- Surface

- Polished / Machined

- Connection

- Welded, Screwed, Threaded

- Technics

- Forged

- Pressure

- 150#, 300#, 600#, 900#, 1500#, 2500#

- Size

- 1/2 to 60 (DN15DN1500)

- Color

- Silver / Metallic

- Yield Strength

- 205 MPa min

- Standards Compliance

- NACE MR0175, IBR Approved

- Hardness

- Rockwell B80 B95

- Type

- Slip On, Weld Neck, Blind, Socket Weld, Threaded, Lap Joint

- Ends

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Density

- 7.9 g/cm

- Temperature Range

- Up to 870C (1600F)

- Tensile Strength

- 515 MPa min

- Elongation

- 35% min

About Stainless Steel 321321H Flanges

What Are Specification Stainless Steel 321/321H Flanges?

| Specifications List | ASTM A182 / ASME SA182 |

|---|---|

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Size Chart | 1/2 (15 NB) to 48 (1200NB) |

| ASTM Standards | ANSI/ASME B16.5, B16.48, BS4504, B 16.47 Series A & B, BS 10, EN-1092, DIN, etc. |

| Standard s | ANSI, ASME, BS, DIN, EN etc. |

Equivalent material Of Stainless Steel 321/321H Flanges?

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

|---|---|---|---|---|

| SS 321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | X12CrNiTi18-9 |

Chemical Composition Of Stainless Steel 321/321H Flanges?

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

|---|---|---|---|---|---|---|---|---|---|

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) 0.70 max |

| SS 321H | 0.04 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 12.00 | 4(C+N) 0.70 max |

Mechanical Properties Of Stainless Steel 321/321H Flanges?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1457 C (2650 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

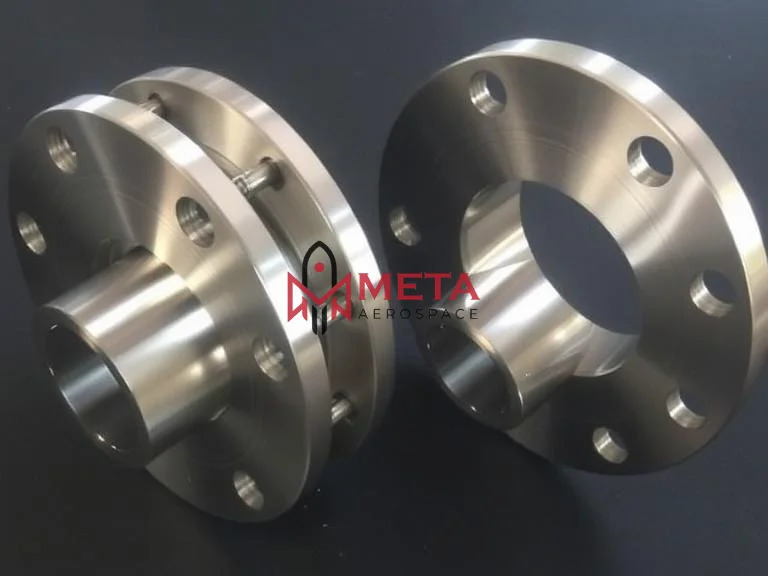

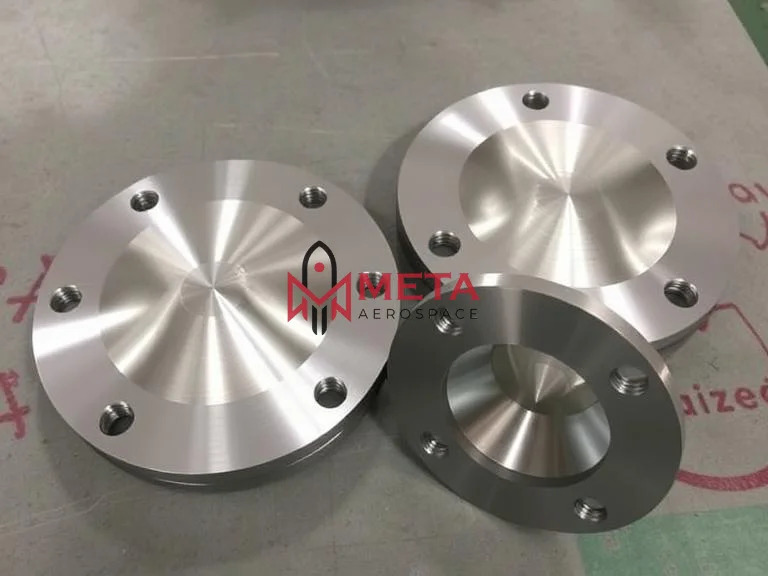

Precision Engineering & Robust Design

Each Stainless Steel 321/321H flange is forged with meticulous attention to dimensional accuracy and surface finish, available in polished or machined options. The combination of precise manufacturing techniques and strict quality control guarantees secure, leak-proof connections under severe temperature and pressure conditions.

Versatile Application Across Industries

With their exemplary corrosion and high-temperature resistance, these flanges are the preferred choice for industries including oil & gas, chemical processing, shipbuilding, and paper & pulp. Their adaptability to various connection types and custom dimensions ensures seamless integration into complex piping systems and infrastructure.

FAQs of Stainless Steel 321321H Flanges:

Q: How are Stainless Steel 321/321H flanges typically used in industrial settings?

A: These flanges are designed for connecting pipes, valves, and other equipment in critical applications, including oil & gas plants, petrochemical complexes, and power generation facilities. Their robust material properties allow them to withstand corrosive substances and high operational temperatures, ensuring safe and long-lasting piping systems.Q: What standards and certifications do Stainless Steel 321/321H flanges comply with?

A: They adhere to globally recognized standards such as ASTM A182, ANSI B16.5, and are also compliant with DIN, JIS, BS, GB, and IS standards. Furthermore, they are NACE MR0175 and IBR approved, confirming their suitability for sour service and boiler regulations, respectively.Q: When should you choose 321/321H grade stainless steel flanges over other types?

A: Select 321/321H flanges when the application demands excellent resistance to high temperatures, up to 870C, and strong performance in environments exposed to corrosive elements, such as acids or chlorides. These grades are ideal for systems requiring both mechanical robustness and stability at elevated temperatures.Q: What are the available connection types and flange faces offered?

A: Connection options include welded, screwed, and threaded types, providing installation flexibility. Available flange faces include Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ), each suited to specific sealing and operational requirements.Q: How does the manufacturing process ensure the durability and precision of these flanges?

A: All flanges are produced through advanced forging techniques, followed by precise machining to obtain the required dimensions and finish. Rigorous inspection throughout production ensures each product meets stringent quality, hardness, and strength specifications.Q: What are the main benefits of using Stainless Steel 321/321H flanges in piping systems?

A: The primary advantages include superior resistance to corrosion and oxidation, high temperature durability, structural reliability, and longevity in challenging operational environments. Their precise dimensions facilitate easy assembly and dependable, leak-tight joints.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Flanges Category

Stainless Steel 310310S Flanges

Material : Stainless Steel

Size : 1/2 NB to 48 NB

Technics : Other, Forged

Surface : Other, Bright, Polished

Standard : Other, ANSI, ASME, DIN, JIS, BS, EN

Purity : 99%

Stainless Steel 317317L Flanges

Material : Stainless Steel

Size : 1/2 to 24 (DN15DN600)

Technics : Other, Forged

Surface : Other, Polished

Standard : Other, ASTM A182 / ASME SA 182

Purity : 99%

Stainless Steel 316316L316H Flanges

Material : Stainless Steel 316, 316L, 316H

Size : 1/2 NB to 48 NB (DN15DN1200)

Technics : Other, Forged / Cast

Surface : Other, Bright, Polished, Antirust oil

Standard : Other, ASTM A182 / ASME SA182, ANSI, DIN, JIS, BS, EN, GOST

Purity : High Purity Stainless Steel

Stainless Steel 304304L Flanges

Material : Stainless Steel 304/304L

Size : 1/2 to 48 (DN15 to DN1200)

Technics : Other, Forged

Surface : Other, Polished / Mirror / Matt finish

Standard : Other, ASME/ANSI B16.5, DIN, JIS, BS and other international standards

Purity : Greater than 99%

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese