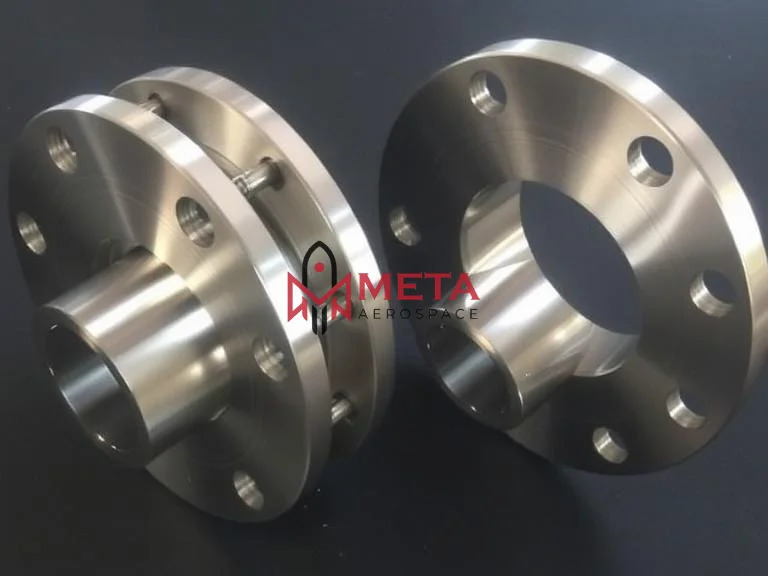

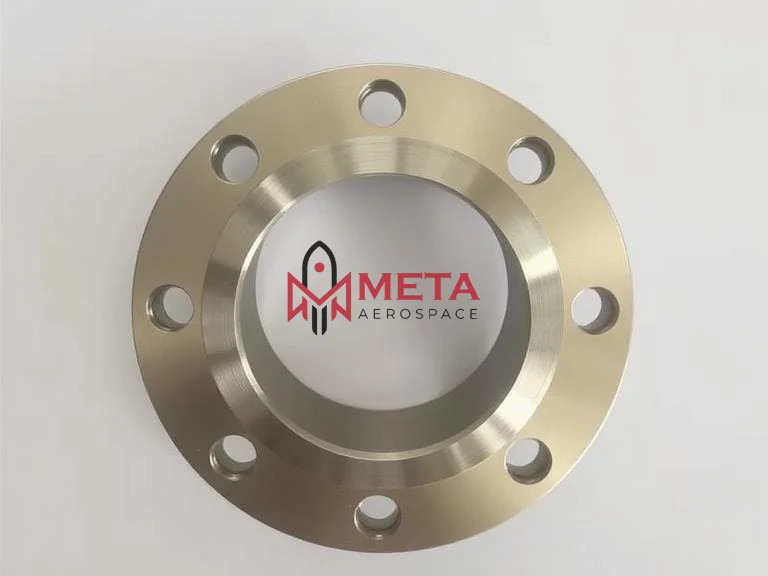

Stainless Steel 316316L316H Flanges

Stainless Steel 316316L316H Flanges Specification

- Dimension (L*W*H)

- As per standard or custom requirements

- Grade

- 316 / 316L / 316H

- Feature

- Corrosion Resistant, Durable, High Strength

- Application

- Chemical, Petrochemical, Power Plant, Oil & Gas, Water Treatment, Food Processing

- Purity

- High Purity Stainless Steel

- Product Type

- Flange

- Material

- Stainless Steel 316, 316L, 316H

- Standard

- ASTM A182 / ASME SA182, ANSI, DIN, JIS, BS, EN, GOST

- Shape

- Round

- Surface

- Bright, Polished, Anti-rust oil

- Connection

- Welded / Screwed / Threaded / Socket Weld / Slip-on

- Technics

- Forged / Cast

- Pressure

- 150# to 2500# (PN6-PN400)

- Size

- 1/2 NB to 48 NB (DN15-DN1200)

- Color

- Silver

- Hardness

- 187 HB Max

- Manufacturing Process

- Hot Forged & Machined

- Nominal Thickness

- 3mm to 60mm

- Elongation

- 30% Min

- Temperature Range

- -196C to +700C

- Face Type

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Tensile Strength

- 515 MPa Min

- Corrosion Resistance

- Excellent in acidic and chloride conditions

- Heat Treatment

- Solution Annealed

- Packaging

- Wooden Cases / Pallets / Custom Packing

- Types Available

- Weld Neck, Slip On, Blind, Socket Weld, Lap Joint, Threaded, Orifice, Ring Type Joint

- End Connection

- Butt Weld, Socket Weld, Threaded

About Stainless Steel 316316L316H Flanges

What Are Specification Stainless Steel 316/316L/316H Flanges?

| Specifications List | ASTM A182 / ASME SA182 |

|---|---|

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Size Chart | 1/2 (15 NB) to 48 (1200NB) |

| ASTM Standards | ANSI/ASME B16.5, B16.48, BS4504, B 16.47 Series A & B, BS 10, EN-1092, DIN, etc. |

| Standard s | ANSI, ASME, BS, DIN, EN etc. |

Equivalent material Of Stainless Steel 316/316L/316H Flanges?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | - | Z7CND17-11-02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17-11-02 / Z3CND18-14-03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | 1.4401 | S31609 | - | - | - | - | - |

Chemical Composition Of Stainless Steel 316/316L/316H Flanges?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 316 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 20 | - | 8 11 | - |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 20 | - | 8 13 | - |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 18 20 | - | 8 10.5 | - |

Mechanical Properties Of Stainless Steel 316/316L/316H Flanges?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1400 C (2550 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 8.0 g/cm3 | 1399 C (2550 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

Versatile Types and Configurations

Choose from an array of flange types such as Weld Neck, Slip On, Blind, Socket Weld, Lap Joint, Threaded, Orifice, and Ring Type Joint to match your project specifications. Available face types include Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ), providing flexibility for different sealing requirements and industry standards.

Exceptional Performance and Durability

Crafted from high-purity Stainless Steel 316, 316L, and 316H, these flanges boast outstanding tensile strength (minimum 515 MPa) and elongation (minimum 30%). They are solution annealed, hot forged or machined, and delivered in customized packaging, ensuring reliable service in severe environments.

Applications Across Critical Industries

Engineered for robust use, these flanges serve the chemical, petrochemical, power plant, oil & gas, water treatment, and food processing industries. Their resistance to corrosive agents and wide operating temperature range make them the preferred choice for demanding environments.

FAQs of Stainless Steel 316316L316H Flanges:

Q: How are Stainless Steel 316/316L/316H flanges manufactured?

A: These flanges are produced using hot forging and machining processes, followed by solution annealing to enhance their strength, durability, and corrosion resistance. They are tailored to meet international standards, ensuring consistent quality for critical applications.Q: What industries benefit most from using these stainless steel flanges?

A: Industries such as chemical processing, oil & gas, water treatment, power generation, and food processing commonly use these flanges due to their excellent corrosion resistance and ability to withstand extreme temperatures.Q: When should I choose 316, 316L, or 316H grade flanges?

A: Select the grade based on your projects requirements: 316 offers standard strength and corrosion resistance, 316L is preferred for its low carbon content and enhanced weldability, and 316H is suitable for high-temperature applications due to its higher carbon content.Q: Where can these flanges be installed?

A: These stainless steel flanges can be safely installed in pipelines, pressure vessels, and process equipment where secure, leak-proof connections are critical, especially in harsh or corrosive environments.Q: What types of connections and pressure ratings are available?

A: You can choose from butt weld, socket weld, threaded, slip-on, and welded connections. Pressure ratings range from 150# to 2500# (PN6 to PN400), accommodating a broad range of system requirements.Q: How do these flanges ensure safety in acidic or chloride-rich environments?

A: Thanks to the superior corrosion resistance of 316 series stainless steels, these flanges prevent failures and maintain integrity even under aggressive chemical or saline conditions, minimizing risk and maximizing service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Flanges Category

Stainless Steel 310310S Flanges

Standard : Other, ANSI, ASME, DIN, JIS, BS, EN

Technics : Other, Forged

Grade : SS 310 / SS 310S

Material : Stainless Steel

Size : 1/2 NB to 48 NB

Surface : Other, Bright, Polished

Stainless Steel 321321H Flanges

Standard : Other, ASTM A182, ANSI B16.5, DIN, JIS, BS, GB, IS

Technics : Other, Forged

Grade : 321 / 321H

Material : Stainless Steel 321/321H

Size : 1/2 to 60 (DN15DN1500)

Surface : Other, Polished / Machined

Stainless Steel 316Ti Flanges

Standard : Other, ASTM A182 / ASME SA182

Technics : Other, Forged / Casting

Grade : 316Ti

Material : Stainless Steel 316Ti

Size : 1/2 to 24 (DN15 to DN600)

Surface : Other, Polished / Smooth

Stainless Steel 317317L Flanges

Standard : Other, ASTM A182 / ASME SA 182

Technics : Other, Forged

Grade : 317 / 317L

Material : Stainless Steel

Size : 1/2 to 24 (DN15DN600)

Surface : Other, Polished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese