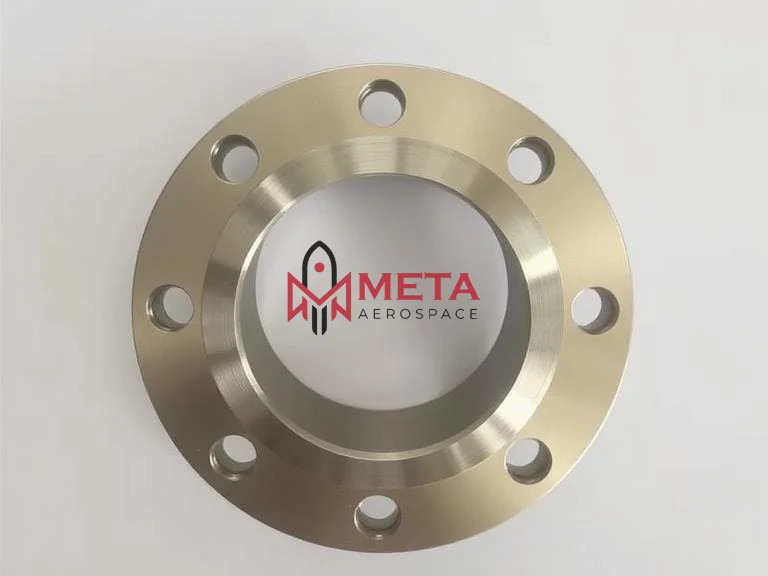

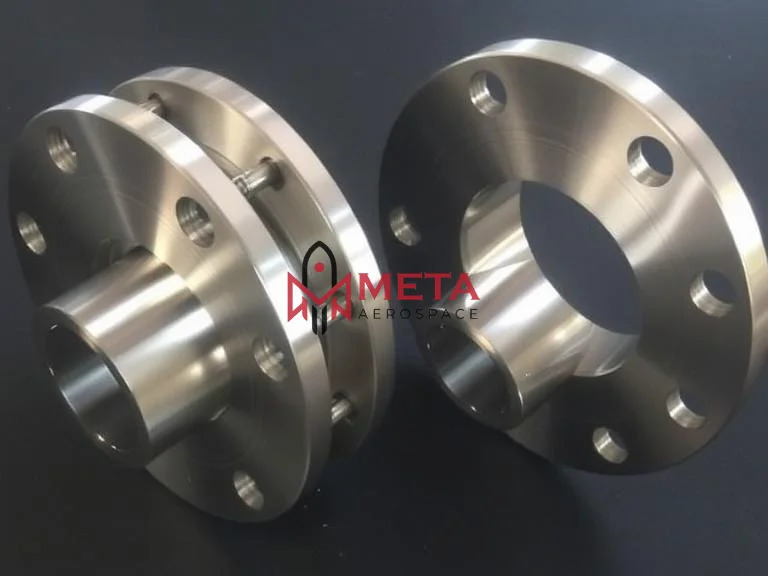

Stainless Steel 316Ti Flanges

Stainless Steel 316Ti Flanges Specification

- Purity

- Premium quality with low carbon content

- Dimension (L*W*H)

- Varies as per size

- Feature

- High Corrosion Resistance, Excellent Strength, Durable

- Application

- Petrochemical, Oil & Gas, Chemical Processing, Power Generation

- Grade

- 316Ti

- Product Type

- Flange

- Material

- Stainless Steel 316Ti

- Standard

- ASTM A182 / ASME SA182

- Shape

- Round

- Surface

- Polished / Smooth

- Connection

- Welded / Bolted

- Technics

- Forged / Casting

- Pressure

- Class 150 to Class 2500

- Size

- 1/2 to 24 (DN15 to DN600)

- Color

- Silver / Metallic

- Heat Treatment

- Solution Annealed

- Packing

- Standard Export Seaworthy Packing

- Elongation

- 35% min

- End Type

- Slip On, Weld Neck, Socket Weld, Blind, Threaded, Lap Joint

- Tensile Strength

- 515 MPa min

- Face Type

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Density

- ~8.0 g/cm

- Hardness

- Brinell 160 HB Max

- Compliance

- ISO, PED, NACE

- Yield Strength

- 205 MPa min

- Melting Point

- 1400C to 1450C

About Stainless Steel 316Ti Flanges

What Are Specification Stainless Steel 316Ti Flanges?

| Specifications List | ASTM A182 / ASME SA182 |

|---|---|

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Size Chart | 1/2 (15 NB) to 48 (1200NB) |

| ASTM Standards | ANSI/ASME B16.5, B16.48, BS4504, B 16.47 Series A & B, BS 10, EN-1092, DIN, etc. |

| Standard s | ANSI, ASME, BS, DIN, EN etc. |

Equivalent material Of Stainless Steel 316Ti Flanges?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17123 | X6CrNiMoTi17-12-2 |

Chemical Composition Of Stainless Steel 316Ti Flanges?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 316Ti | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 16.00 18.00 | 2.00 3.00 | 10.00 14.00 | 68.395 min |

Mechanical Properties Of Stainless Steel 316Ti Flanges?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1399 C (2550 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

Unmatched Corrosion Resistance

With the inclusion of titanium in grade 316Ti, these stainless steel flanges offer robust resistance to corrosion, especially in aggressive and high-temperature applications. The premium quality, low carbon content, and precise forging or casting guarantee long-term performance, making them suitable for harsh industrial environments.

Comprehensive Range of Face and End Connections

Choose from Raised Face (RF), Flat Face (FF), or Ring Type Joint (RTJ) face types, paired with end types like Slip On, Weld Neck, Socket Weld, Blind, Threaded, or Lap Joint. This extensive variety provides compatibility with diverse piping systems, ensuring a proper fit and safe, reliable connections for every project requirement.

Engineered for Strength and Durability

Manufactured to meet strict ISO, PED, and NACE standards, Stainless Steel 316Ti Flanges achieve a minimum tensile strength of 515 MPa and yield strength of 205 MPa with 35% minimum elongation. Solution annealing further enhances their mechanical properties, guaranteeing reliability, even under high pressure and temperature conditions.

FAQs of Stainless Steel 316Ti Flanges:

Q: How are Stainless Steel 316Ti Flanges commonly used in industrial applications?

A: These flanges are widely utilized in industries such as petrochemical, oil & gas, chemical processing, and power generation. Their high corrosion resistance and strength make them ideal for connecting pipelines, valves, and equipment that handle corrosive fluids or operate at elevated temperatures.Q: What are the main face types available for Stainless Steel 316Ti Flanges and how do they differ?

A: 316Ti flanges are available with Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ). RF is widely used for high-pressure applications and provides a better seal. FF is suitable for low-pressure environments or systems using cast iron valves. RTJ is preferred for critical, high-pressure connections requiring metal-to-metal sealing.Q: When should I choose a Weld Neck versus a Slip On or Socket Weld flange end type?

A: Weld Neck flanges are best for high-pressure, high-temperature environments due to their superior strength and resistance to dishing. Slip On flanges are easier to install and suitable for lower-pressure systems, while Socket Weld flanges are used for small-diameter, high-pressure pipelines where tight connections are necessary.Q: What processes are used in the manufacturing of these flanges?

A: Stainless Steel 316Ti Flanges are produced using precise forging or casting methods, followed by solution annealing heat treatment. This process enhances their corrosion resistance and mechanical strength, resulting in a durable and long-lasting product.Q: Where are these flanges typically exported or supplied from?

A: They are primarily manufactured, exported, supplied, and traded from India by specialized companies who follow international standards like ASTM, ASME, ISO, PED, and NACE to ensure quality and compliance for global markets.Q: What are the key benefits of choosing Stainless Steel 316Ti over standard stainless steels?

A: 316Ti contains titanium, improving its resistance to intergranular corrosion at high temperatures. This longevity and reliability in harsh environments surpass standard 304 or 316 grades, making 316Ti flanges excellent for demanding chemical, petrochemical, and power generation operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Flanges Category

Stainless Steel 317317L Flanges

Technics : Other, Forged

Grade : 317 / 317L

Material : Stainless Steel

Surface : Other, Polished

Standard : Other, ASTM A182 / ASME SA 182

Purity : 99%

Stainless Steel 310310S Flanges

Technics : Other, Forged

Grade : SS 310 / SS 310S

Material : Stainless Steel

Surface : Other, Bright, Polished

Standard : Other, ANSI, ASME, DIN, JIS, BS, EN

Purity : 99%

Stainless Steel 316316L316H Flanges

Technics : Other, Forged / Cast

Grade : 316 / 316L / 316H

Material : Stainless Steel 316, 316L, 316H

Surface : Other, Bright, Polished, Antirust oil

Standard : Other, ASTM A182 / ASME SA182, ANSI, DIN, JIS, BS, EN, GOST

Purity : High Purity Stainless Steel

Stainless Steel 321321H Flanges

Technics : Other, Forged

Grade : 321 / 321H

Material : Stainless Steel 321/321H

Surface : Other, Polished / Machined

Standard : Other, ASTM A182, ANSI B16.5, DIN, JIS, BS, GB, IS

Purity : >99%

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese